Ultra-high precision

3D Laser Profiler with the fastest scanning speed (67kHz)

With the largest number (6400) of X-axis points

Discover SinceVision high-speed camera solutions, offering precision imaging and fast frame rates for industrial and machine vision applications.

SinceVision industry-leading 3D Laser Profilers with 6400 X-axis profile points and Z-axis repeatability accuracy up to 0.1μm.

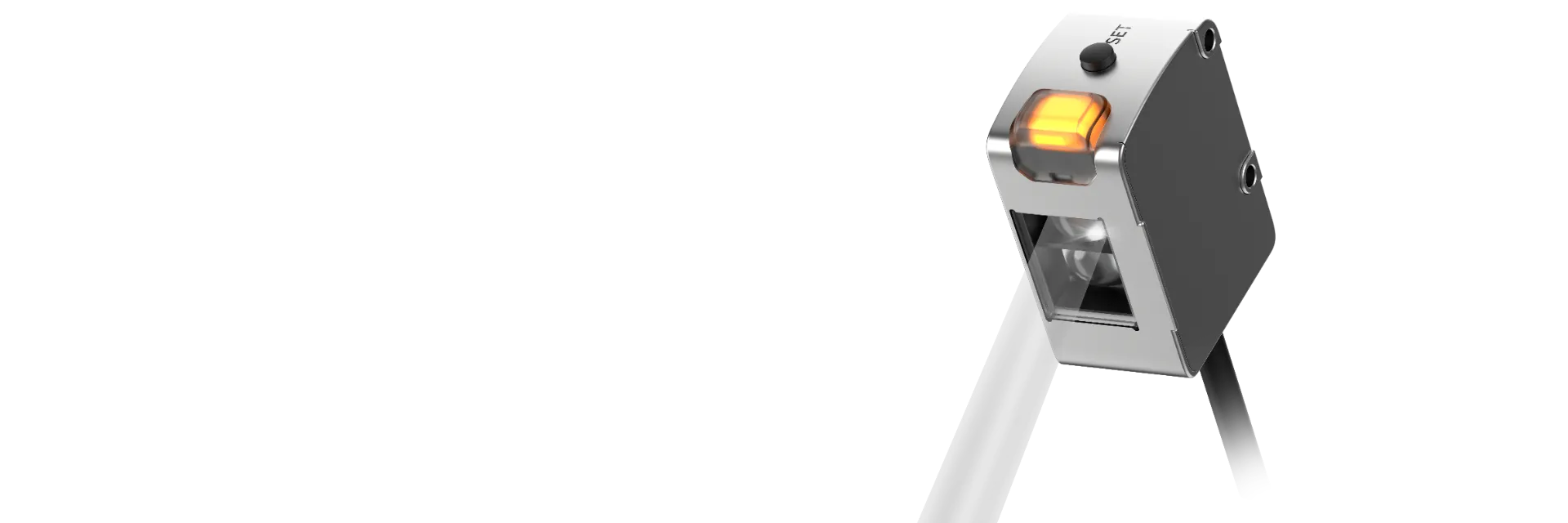

Explore SinceVision Laser Displacement Sensor, designed for high-accuracy distance measurement in automation and inspection applications. Ideal for precise, reliable results in industrial settings.

SinceVision Spectral Confocal Displacement Sensor for accurate, non-contact displacement and thickness measurement across various materials. Perfect for high-precision industrial inspection needs.

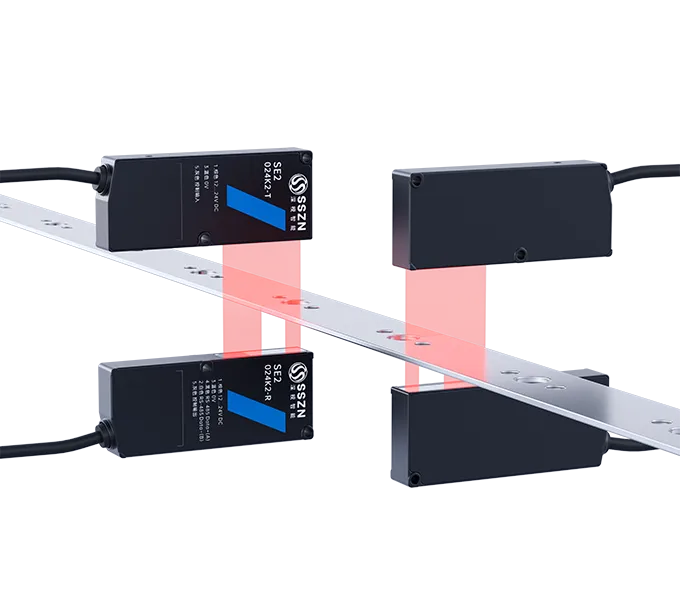

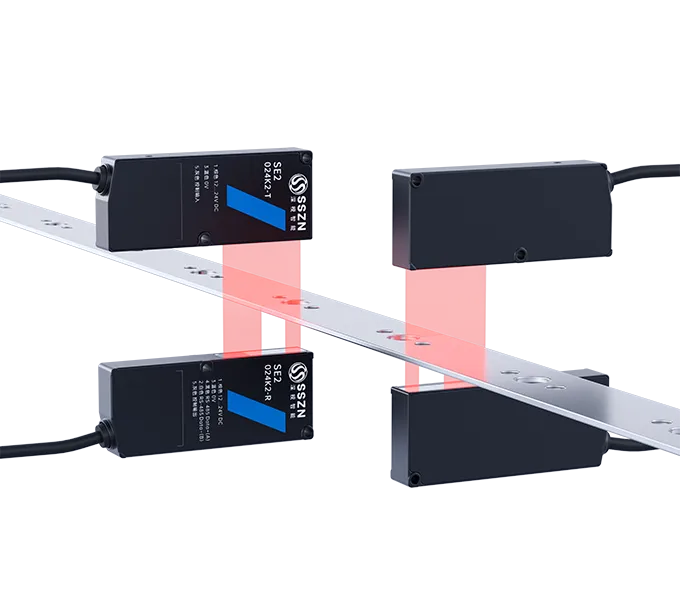

SinceVision Through-Beam Edge Sensor, offering non-contact, high-speed edge detection for precise positioning. Ideal for web edge control, sheet metal detection, and quality control across multiple industries.

SinceVision Through-Beam Edge Sensor, offering non-contact, high-speed edge detection for precise positioning. Ideal for web edge control, sheet metal detection, and quality control across multiple industries.

SinceVision Full-Spectrum Sensor, is engineered for precise color detection across a full spectrum. Perfect for high-precision industrial automation and quality control applications.

3D Laser Profiler with the fastest scanning speed (67kHz)

With the largest number (6400) of X-axis points

Standard memory for all series products starting from 40GB (Up to 24TB)

Record of up to 1 million pixels, delivering unmatched clarity and precision

Laser Displacement Sensor SG5000 series

With the highest sampling frequency (590kHz)

Spectral Confocal Displacement Sensor

Maximum mirror measurement angle ±60°

Full-Spectrum Sensor

Adopts RS485 communication mode, with response time as short as 200μs

Automotive

Enabling over 100 subdivisions

Proportion of R&D technicians