In the fast world of making semiconductors, getting every detail right is key. This is especially true during wafer production. The size and shape of silicon rods directly affect the quality of wafers sliced from them. A rod with dimension errors, surface defects, or hidden flaws like bubbles or voids can lead to unusable or unreliable wafers. These inconsistencies lower yield rates and increase production costs. Manufacturers want reliable, automated inspection tools as production lines become more advanced. This helps them ensure high-quality output. SinceVision’s SRI8060 3D Laser Profiler sets a new standard for measuring silicon rod dimensions.

Traditional Inspection Challenges

Previously, inspecting silicon rods was mostly done using manual methods or simple sensors. These methods worked well in slower, low-volume settings. But now, they don't fit in today's fast, automated factories. Manual inspections take a lot of time and can be inconsistent. Single-sensor solutions often overlook small structural details. They also lack the processing power to deliver real-time insights. The semiconductor industry is moving toward digitalization and smart manufacturing. This makes the need for fast, accurate, and automated inspection systems urgent.

SinceVision’s High-Precision Solution - SRI8060

SinceVision met industry needs by introducing the SRI Series Integrated 3D Laser Profiler. The SRI8060 model is designed for tasks such as checking silicon rod quality and measuring wafer production. With exceptional Z-axis repeatability of 0.2μm, the sensor delivers highly detailed surface and shape data. Its 20kHz sampling rate allows quick scanning. This makes it perfect for busy semiconductor production lines. The system has a compact, all-in-one design. This means no need for external controllers. It fits into tight factory spaces without difficulty and requires a straightforward installation.

Case Study: 360° Silicon Rod Inspection

The SRI8060 recently proved effective in a real-world production setting. The inspection focused on silicon rods measuring 210mm by 210mm with a height of 100mm.

The manufacturer needed exact measurements for:

1. Arc length projection

2. Edge margins

3. Diameters

4. Straight edge angles

Accuracy standards were strict: ±0.04mm for arc length projection, ±0.02mm for edge margins and diameter, and ±0.02 degrees for angles. Additionally, the inspection process needed to complete each rod scan within 60 seconds to keep up with production line speed.

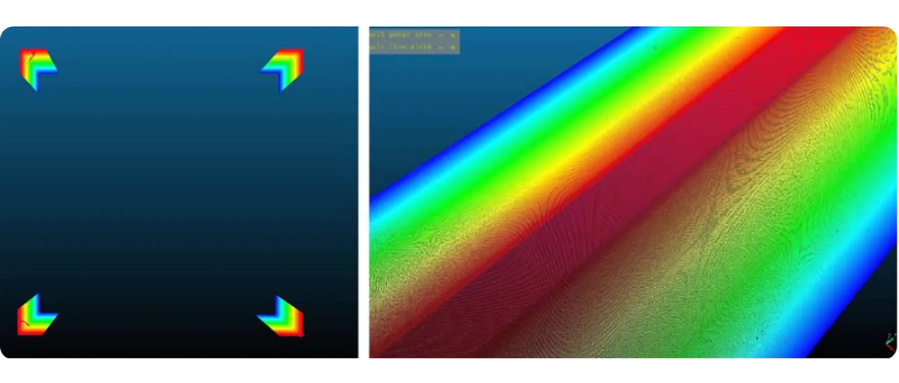

SinceVision engineers installed four SRI8060 3D laser profilers on a circular rail. They spaced them 90 degrees apart. This setup allows for a complete 360° scan of the silicon rod’s surface. The rod moved smoothly through the system. All four sensors captured real-time 3D point cloud data from every angle at the same time. The system's software quickly processed the data. It used gray-scale image enhancement and point cloud stitching algorithms. This ensured high-resolution images with no data blind spots.

Data Processing and Measurement Accuracy

Figure | Left: Point cloud front view Right: Point cloud details

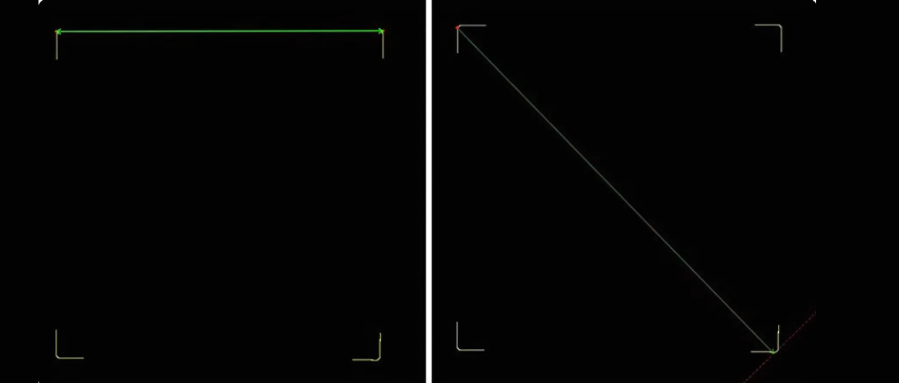

Figure | Left: Point cloud cropped ROI Right: Point cloud cross-section outline

After collecting the point cloud data, the system cropped it with a Region of Interest (ROI). This step removed unnecessary details. It extracted the rod's outer shape. Then, it calculated the exact measurements for arc length, edge distance, diameter, and angle. The system showed great repeatability after 32 static test scans in a controlled setting. Arc length projection showed a deviation of just 0.003mm, edge margin 0.0051mm, diameter 0.0048mm, and angle 0.0088 degrees. The results not only met the customer’s strict quality standards but also exceeded them. The SRI8060 is ideal for precision jobs. It's great for tasks like inspecting silicon rods in semiconductor manufacturing.

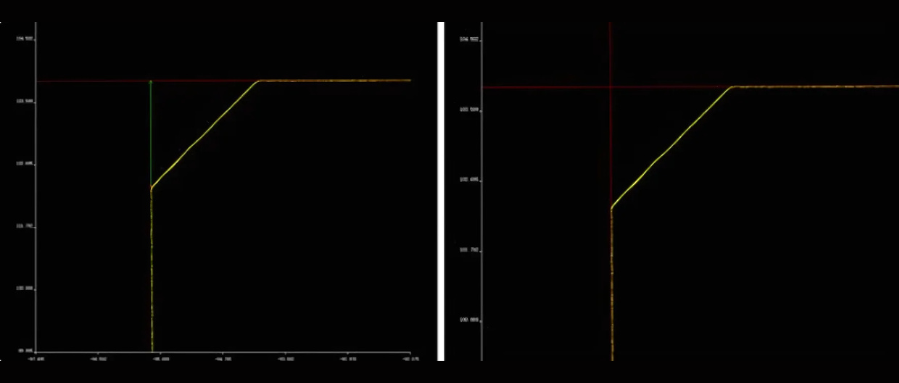

Figure | Left: Margin (side length) Right: Center margin

Figure | Left: Arc length projection Right: Straight edge angle (perpendicularity)

Researchers obtained these figures under lab conditions. Real-world results may differ slightly depending on environmental variables and line conditions. The performance shows that the system is stable and accurate. This gives semiconductor manufacturers confidence in quality control.

Scalable Technology for Broader Applications

The SRI8060 laser profiler goes beyond inspecting silicon rods. It’s designed to handle many high-tech inspection tasks. Its modular structure and processing power make it suitable for photovoltaic wafer thickness measurement, semiconductor packaging defect detection, and other high-speed, precision 3D scanning applications. Thanks to its flexible design and advanced software, manufacturers can easily scale the system. They can adapt it for different production lines and product types. This process does not require major reconfiguration.

Why Choose SinceVision

SinceVision’s SRI Series profilers do more than measure quickly. They lead to smarter, more accurate, and automated manufacturing. The SRI8060 gives semiconductor producers clear benefits. It helps them improve yield, cut rework, and keep tight tolerances. It offers super-fine measurement, quick scanning, and easy setup. It also supports smart factory goals.

Manufacturers globally choose SinceVision for next-gen quality control tools. These tools boost efficiency and make products more reliable. No matter if you’re making silicon rods, checking wafers, or managing complex packaging lines, the SRI Series gives you the tools to compete at the top level.

Learn More

Ready to boost your semiconductor manufacturing? Visit SinceVision’s product page or contact us for a free consultation, sample, and demo.

-

Industry News2025-12-15Solving Measurement Challenges in Opaque and Semi-Transparent Glue Inspection with SinceVision 3D Laser Profiler

-

Industry News2025-12-05Machine Vision Sensor Solutions in Automotive Manufacturing | SinceVision Application Cases

-

Corporate News2025-12-02SinceVision to Exhibit Advanced Imaging and Sensing Technologies at SPIE VISION TECH 2026

-

Corporate News2025-11-17SinceVision Launches New Back-Illuminated Cooled sCMOS Camera Series for Ultra-Low-Light Scientific Imaging