Advanced Non-Contact Sensors Cut Costly Overlaps in High-Speed Production

Printed Circuit Boards (PCBs) are vital for electronic devices. They provide mechanical support and key electrical connections. The precision of these components affects reliability, performance, and lifespan. As devices shrink, the demand for thinner, multi-layered PCBs increases.

This trend introduces new ideas but also significant challenges. Ultra-thin PCBs are prone to accidental overlaps during high-speed manufacturing. On busy production lines, small misalignments or vibrations can cause PCBs to stack incorrectly.

Traditional inspection systems struggle to detect these overlaps. They often rely on outdated contact methods or low-resolution optics. Missed detections can increase scrap rates and lead to costly damages or total product failures. This can result in millions of dollars in waste for manufacturers each year.

How Does a 5μm Repeatability Sensor Prevent Circuit Board Defects?

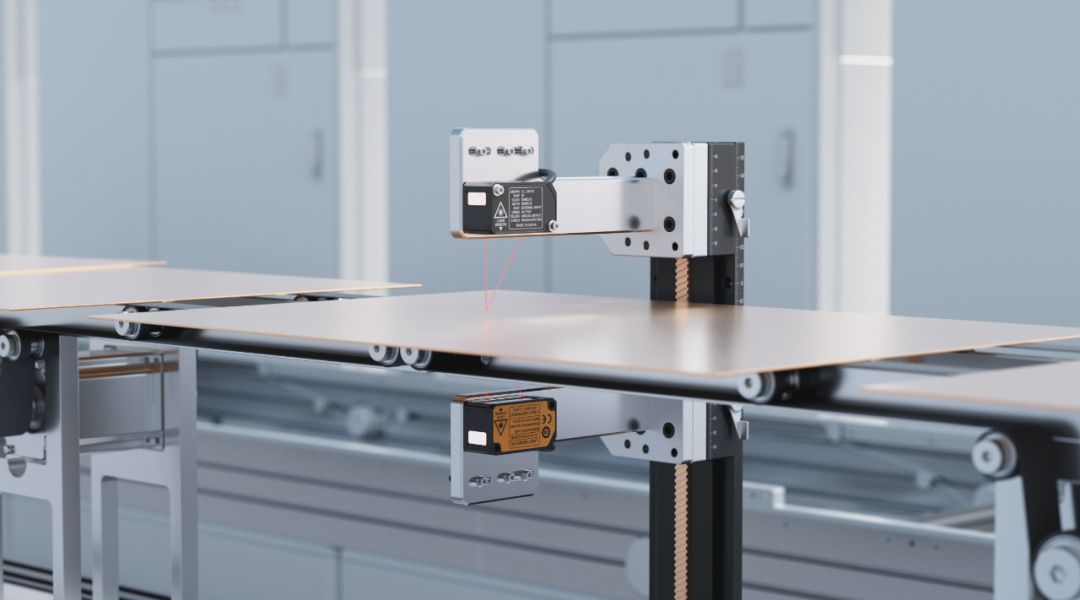

To address these manufacturing challenges, we need better inspection methods. We should focus on accuracy, reliability, and non-contact techniques. Engineers designed the SinceVision SD-C030 miniature laser displacement sensor for precision-critical tasks. It offers a superior non-contact solution, avoiding issues like wear and optical clarity.

This maintains accuracy and protects delicate PCBs. The SD-C030 is compact and cost-effective, featuring industrial-grade sensors for precise measurements. It provides real-time feedback in busy production settings.

Its main advantage is detecting tiny thickness changes in PCBs. These measurements are crucial for identifying unintended multilayer overlaps during assembly or handling. With high resolution and fast sampling, it can detect thickness changes at the micrometer level. It flags defective boards early, preventing them from moving further down the line. This helps avoid costly problems later and ensures inline PCB defect detection.

Precision Engineering for Multilayer PCB Overlap Detection

The SD-C030 is expertly designed for fast PCB inspection in modern electronics manufacturing. It has a detection distance of 30mm and a measurement range of ±5mm. This flexibility accommodates various PCB sizes and layouts. Its linearity of ±0.1% Full Scale (F.S.) ensures accurate measurements, while the Φ50μm laser spot focuses precisely on narrow PCB surfaces. The device samples at 100–1000Hz, quickly detecting PCB defects on fast production lines.

Importantly, the SD-C030 integrates seamlessly into existing automation systems. It supports RS-485 and outputs analog voltage and current. This makes it compatible with many control systems for real-time data exchange.

This means the sensor can monitor the height of each PCB layer as it passes by. If thickness exceeds set tolerances, the sensor triggers an audio-visual alarm. This early alert stops defective boards from moving to later steps. This lowers scrap, rework, and machine downtime a lot. The SD-C030 features a big, front-facing status light. This gives operators quick feedback on inspection conditions. This enhances transparency and responsiveness in the production process.

The sensor has also passed CE, RoHS, and EMC certifications. This shows it is durable and meets global standards. It stays stable and accurate, even in tough factory conditions like heat and electromagnetic interference. Its compact size of 44.4 × 25 × 20mm allows for mounting in tight spaces within complex machinery. This design enables high-precision inspection in areas where access was previously limited.

SD-C030: A Flagship Sensor for Broader Automation Applications

The SD-C030 is the top model in SinceVision’s SD-C Series. It shows the company’s dedication to high-quality industrial sensors. Vision's skills in industrial sensing make the SD-C030 a great choice for real manufacturing needs. Its 5μm repeatability and 50μm laser spot make it great for PCB multilayer overlap detection. Plus, it processes data quickly, so it’s perfect for precision inspection tasks.

Beyond PCBs, this miniature laser displacement sensor is suitable for various automation contexts. It is great for measuring surface height, positioning objects, and inspecting dimensions. This applies to the semiconductor, electronics, and precision machinery industries.

Its RS-485 communication and analog I/O let system integrators connect easily to PLCs, vision systems, or edge computing nodes. Designed for easy use, the SD-C030 has three function buttons and an LED display. These features simplify installation, calibration, and operation, even in demanding settings.

Manufacturers need to invest in high-accuracy displacement sensors. This helps boost yield, cut waste, and improve process visibility. The SD-C030 is ready for the future. It fits industry trends like miniaturization, digitization, and real-time process control.

Conclusion: Pioneering Precision in Electronics Manufacturing

The SD-C030 from SinceVision is a game-changer in non-contact thickness measurement for electronics. Its compact design, high resolution, and industrial-grade stability set it apart. It solves a common quality control issue: finding multilayer PCB overlaps quickly. Manufacturers can use sensors such as the SD-C030.

This helps improve process reliability and product consistency. This also helps cut costs from inspection failures and waste. As automation increases, precision sensing tech remains vital for smarter and more efficient production lines.

Ready to eliminate costly PCB overlaps and elevate your electronics manufacturing?

The SD-C030 is more than a sensor; it's your strategic advantage for flawless production. Don’t let hidden defects damage your product’s performance or your brand’s reputation. Visit product page or contact our expert team today for a personalized consultation or demo. Take the step toward smarter, more efficient, and more reliable production lines.

-

Industry News2025-12-15Solving Measurement Challenges in Opaque and Semi-Transparent Glue Inspection with SinceVision 3D Laser Profiler

-

Industry News2025-12-05Machine Vision Sensor Solutions in Automotive Manufacturing | SinceVision Application Cases

-

Corporate News2025-12-02SinceVision to Exhibit Advanced Imaging and Sensing Technologies at SPIE VISION TECH 2026

-

Corporate News2025-11-17SinceVision Launches New Back-Illuminated Cooled sCMOS Camera Series for Ultra-Low-Light Scientific Imaging