As lithium battery demand surges across EVs, energy storage, and portable electronics, quality control during mid-stream cell formation is critical. SinceVision is helping manufacturers meet these demands with a full suite of high-speed, non-contact sensing solutions from foil residual detection to precise welding inspection. These advanced sensors reduce defects, improve yield, and support efficient automation on the lithium battery production line.

Cell winding and welding are critical stages prone to defects. SinceVision addresses the challenges of dynamic scenarios with a combination of high-response and anti-interference sensors:

Application of 3D Laser Profiler in Lithium Battery Manufacturing

A. Coating and Calendering Electrode Embossing

Using the SinceVision SR Series 3D Laser Profiler to scan the convex points on the electrode surface, with a measurement repeatability accuracy of 0.1μm, precisely controls the embossed morphology of the electrode. It measures the depth and width of the convex points on the electrode surface after embossing.

They meet the design requirements, avoiding morphological differences caused by excessive or insufficient depth, thereby ensuring the consistency of battery performance. The sensor's operating speed reaches 800mm/s, meeting the efficiency requirements for high-speed winding and embossing inspection.

B. Post-Welding Defect Detection of Connecting Piece

SinceVision's SR Series 3D laser profiler simultaneously outputs brightness and height maps, precisely measuring weld mark width, area, and appearance. It synchronously locates the weld trace and obtains defect depth information.

It enables quantitative analysis of welding quality and efficient identification of defects such as spatter, cold welds, and weld bead deviation. This assists the production line in timely removal of defective products, reducing potential risks to cell performance and downstream processes.

C. Top Cover Step Gap Detection

SinceVision's SR Series 3D laser profiler has a detection capability for gap width ≥0.05mm and step height ≥0.25mm. It can precisely measure the step height difference and gap after cell crimping. 3D sensor profile analysis and 3D modeling analysis.

It provides precise dimensional data support for top cover welding, avoiding risks such as poor welding and sealing failure caused by excessive gaps or steps, and builds a high-precision pre-processing inspection system for the quality control of lithium battery top cover welding.

D. Top Cover Post-Welding Quality Inspection

SinceVision's SR Series 3D laser profiler, through single-camera forward and reverse scanning or dual-camera coordinated scanning of the long sides, short sides, and R-corners of the lithium battery top cover welds, simultaneously outputs 3D point clouds and brightness maps. It can precisely detect welding defects such as spatter and pits, preventing issues like electrolyte leakage from the cells, and meets the requirements for high-quality weld defect detection.

E. Sealing Nail Post-Welding Quality Inspection

SR Series 3D laser profiler, through single-camera forward and reverse scanning or dual-camera coordinated scanning, with a high X-axis resolution of 5μm. It precisely acquires three-dimensional point cloud and grayscale image data of the weld bead.

This enables full-dimensional morphology analysis of complex curved welding areas, efficiently identifying defects such as spatter, craters, pinholes, and incomplete welds, reducing the risk of electrolyte leakage and meeting the high-quality inspection requirements for the appearance of sealing nail welds.

F. Appearance & Dimension Inspection of Wrapped Cell

SR Series, relying on high-precision point cloud data acquisition and depth information analysis. It precisely identifies defects such as bubbles, wrinkles, and scratches on the blue film surface (defect criteria: height/depth/width ≥0.2mm, wrinkle/scratch length ≥2mm can be detected).

Simultaneously, with a cell dimension tolerance detection capability of 0.3mm, it performs dual-camera opposed measurement of the cell's length and width. This ensures that the appearance and dimensions of the five sides of the wrapped cell (excluding the top cover) meet process standards, thereby ensuring the assembly accuracy, safety, and overall performance of the cell.

Application of Laser Displacement Sensor in Lithium Battery Manufacturing

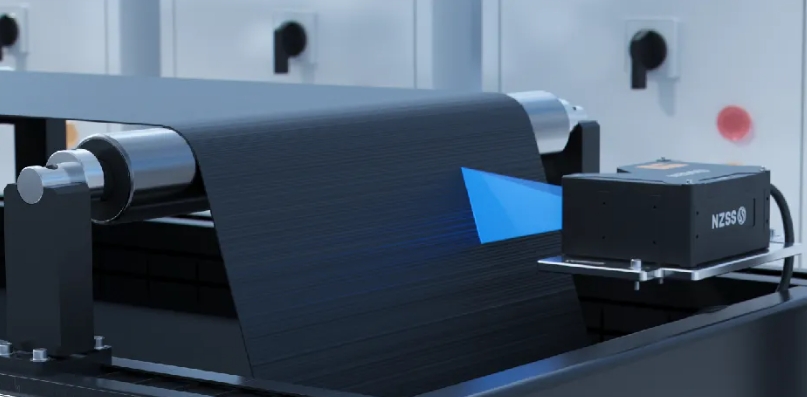

G. Unwinding Residual Material Detection

SD-C Series laser displacement sensor enables real-time acquisition of roll residual material diameter data and precise calculation of remaining material length. The laser displacement sensor has a 200mm~600mm detection distance and 0.2mm repeatability accuracy, enabling dynamic monitoring of residual material within a 400mm range, which can meet the residual material detection needs of rolls with different diameters.

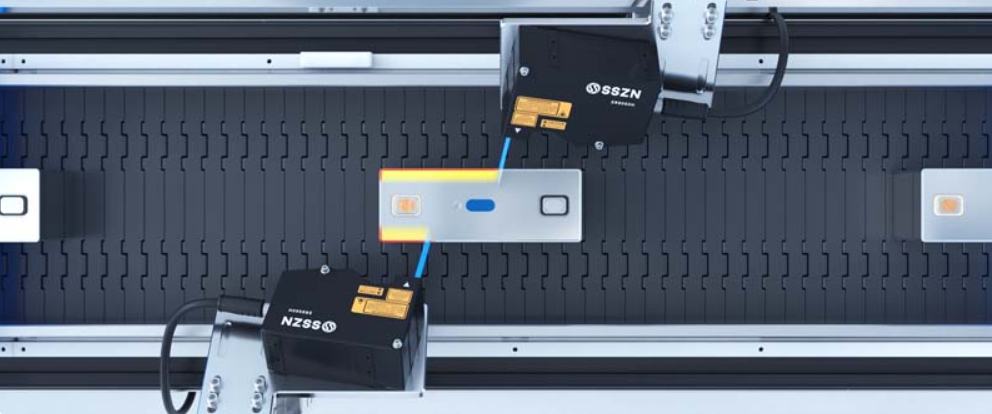

H. Detection of Welding Defocusing Amount of Connecting Piece

SinceVision's SD-C Series laser displacement sensor, with a focusing error detection capability of ≤0.03mm. It precisely measures the height deviation of the welding surface, calculates and feeds back the defocusing amount in real time. It also assists welding equipment in dynamically adjusting the focal length.

SD-C Series effectively reduces the risk of welding defects such as false welding and burn-through caused by abnormal defocusing amount. It also provides sub-millimeter level precision detection for the welding of connecting pieces and electrode tabs, ensuring high-quality welding.

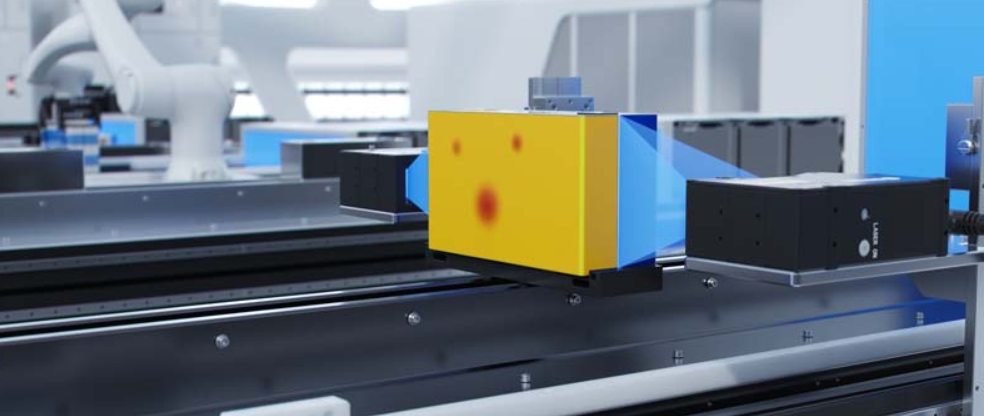

I. Top Cover Welding Defocusing Amount Detection

SD-C Series laser displacement sensor has a focusing error detection capability of ≤0.03mm. It can measure and provide real-time feedback of defocusing amount data and assisting welding equipment in dynamically adjusting the focal length. It also effectively reduces the risk of welding defects such as cold welds and burn-through caused by abnormal defocusing amounts.

SD-C Series provides sub-millimeter level precision distance detection for high-quality welding of the top cover and the casing. This ensures the sealing performance and structural reliability of the cell packaging process.

Application of Through-Beam Edge Sensor in Lithium Battery Manufacturing

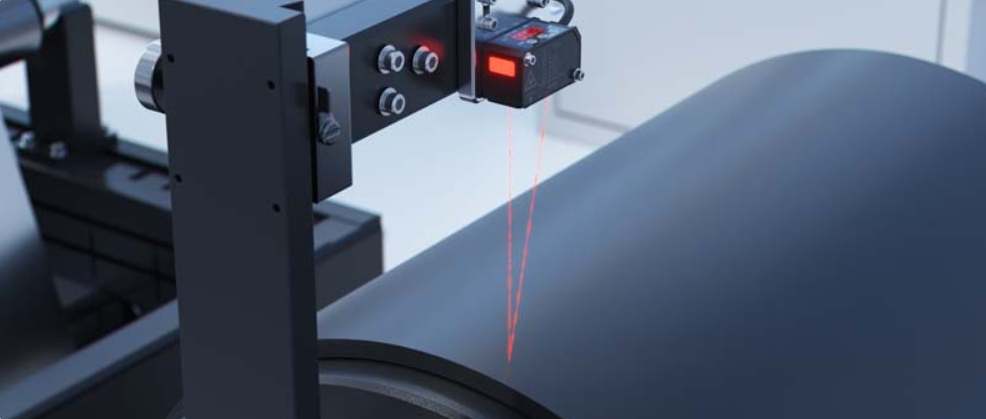

J. Electrode Unwinding Deviation Correction

SinceVision's SE2 Series through-beam edge measurement sensor is equipped with EtherCAT communication, eliminating the need for an additional controller. The communication module supports a one-to-four configuration and has strong anti-interference capabilities. The sensor features a 24mm wide measurement range and 0.1mm high-precision edge positioning capability, enabling real-time acquisition of the electrode edge position during transmission and automatic deviation correction to ensure edge alignment and prevent electrode misalignment.

K. Electrode Winding Alignment Correction

SinceVision's SE1 Series through-beam edge measurement sensor, with a 4kHz sampling frequency and 5μm repeatability accuracy, captures minute deviations in the electrode edge in real time. It precisely identifies damage defects as small as 1.5×1.5mm and simultaneously enables real-time output and visual monitoring of detection data, preventing quality issues caused by misalignment or damage notches on the edges of the battery cell electrodes.

Application of Full-Spectrum Sensor in Lithium Battery Manufacturing

L. Warning Tape Identification

Addressing the detection challenges caused by the reflective surface of the tape, SS1 Series full-spectrum sensor employs an anti-high-reflection interference design and precise light intensity sensing technology to reliably identify electrode connection tape, end-of-roll tape, and defective tape. With a 5kHz high-frequency sampling rate and reliable threshold determination, it assists equipment in automatically locating and cutting tape positions, effectively reducing the risk of abnormal electrode connections caused by missed or false tape detections, ensuring the continuity and yield rate of cell production.

M. Polarity Identification of Connecting Piece

Using SinceVision's SS1 Series full-spectrum sensor, relying on a high-sensitivity color recognition algorithm and anti-ambient light interference design, precisely identifies the installation direction and matching status of the connecting piece and the electrode tab. It assists automated equipment in completing the rejection and early warning of incorrect materials, avoiding risks such as welding failure and abnormal circuit connections caused by deviations in the connecting piece installation, providing stable detection guarantees for the reliability and consistency of the cell assembly process.

From the unwinding stage to top cover welding, SinceVision’s industrial sensors are setting new standards for precision and reliability in lithium battery manufacturing. With high-speed sampling, micron-level accuracy, and smart integration features, these solutions ensure each battery cell meets the highest quality standards.

Visit Contact us page to request a sample, demo, or learn how to integrate SinceVision into your battery production line.

-

Industry News2025-12-15Solving Measurement Challenges in Opaque and Semi-Transparent Glue Inspection with SinceVision 3D Laser Profiler

-

Industry News2025-12-05Machine Vision Sensor Solutions in Automotive Manufacturing | SinceVision Application Cases

-

Corporate News2025-12-02SinceVision to Exhibit Advanced Imaging and Sensing Technologies at SPIE VISION TECH 2026

-

Corporate News2025-11-17SinceVision Launches New Back-Illuminated Cooled sCMOS Camera Series for Ultra-Low-Light Scientific Imaging