Lithium battery manufacturing demands exceptional precision to ensure product safety, performance, and reliability. Any defects in electrodes, coatings, welds, or assembly can lead to significant performance degradation and safety hazards. For example, short circuits or thermal runaway, and costly material waste. Traditional inspection methods often fall short in detecting subtle three-dimensional defects or maintaining real-time, non-destructive monitoring on high-speed production lines.

The Limitations of Traditional Inspection Methods

Conventional inspection techniques in battery production primarily rely on two-dimensional vision systems or manual sampling. These methods present several significant challenges:

Limited detection capability: 2D vision cannot capture depth or surface variations critical for coating thickness or embossed features.

Slow and destructive: Manual sampling interrupts production and may damage samples, failing to provide comprehensive quality data.

Inadequate for dynamic lines: Many 2D methods cannot keep pace with the rapid speeds of modern battery manufacturing lines.

These limitations highlight the need for advanced, high-precision inspection technologies capable of accurate, real-time 3D measurement under industrial conditions.

Introduction to 3D Laser Profiling Technology

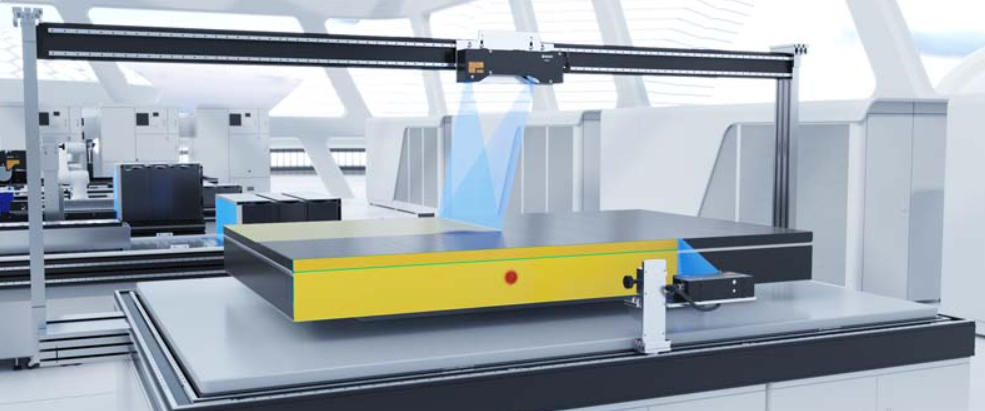

SinceVision’s SR Series 3D Laser Profiler is a high-speed laser measurement sensor designed to meet the rigorous demands of lithium battery inspection. It employs a laser line projection onto a target surface, capturing detailed three-dimensional profile data, including height, width, and depth in real time.

Key technical specifications include:

X-axis contour resolution: up to 6400 points

Scanning speed: up to 67,000 Hz

Z-axis linearity: ±0.02% of full scale (F.S.)

This combination enables thousands of profiles per second to be scanned on moving production lines with micron-level accuracy, even in environments with vibration, dust, and variable lighting.

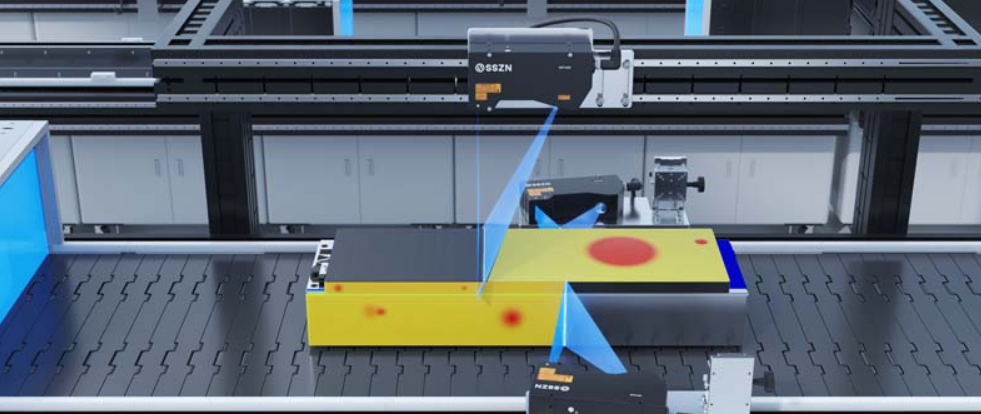

Applications in Lithium Battery Production

SinceVision’s SR Series 3D Laser Profilers improve quality control across the entire lithium battery manufacturing process. The following outlines 13 critical applications demonstrating this technology’s versatility and effectiveness.

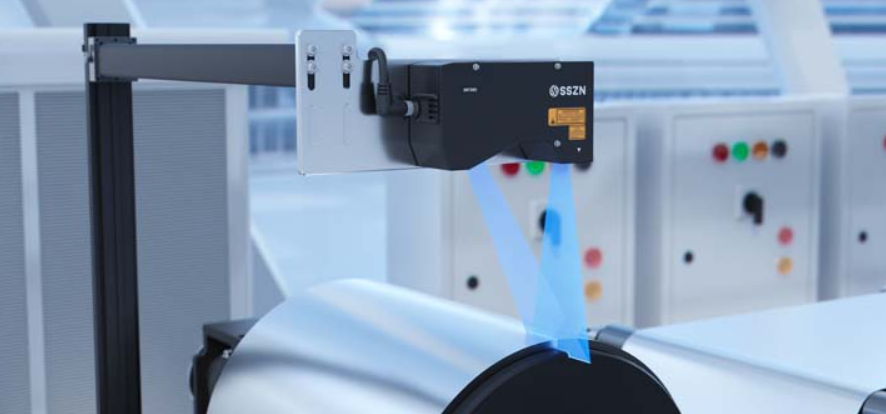

Foil Material Residue Inspection

Using the SR7300 model, manufacturers can inspect foil materials with an effective range of up to 288mm and achieve a repeatability accuracy of 0.1mm. The system samples up to 20kHz/s, supporting production speeds of 80m/min. It collects real-time thickness data to calculate remaining residue length accurately, reducing material losses from coating residues and foil roll changes while improving yield.

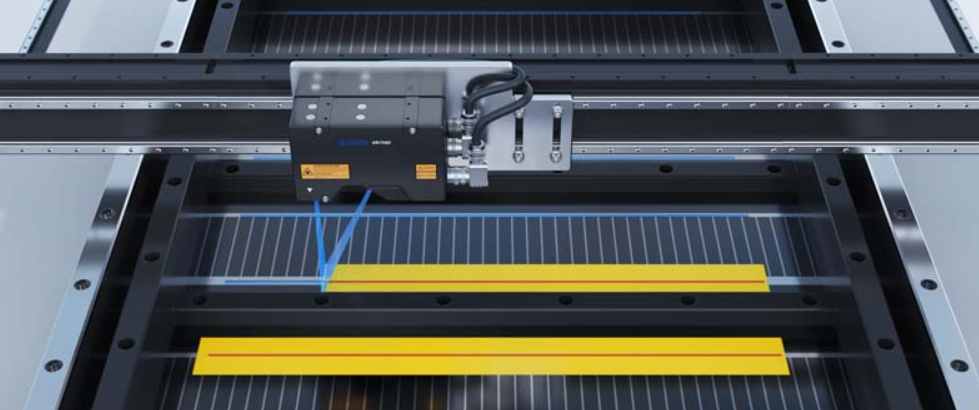

Coating Roller Pressing and Electrode Slitting

The SR9520 laser profiler achieves 0.3μm repeatability to measure slit depth and width on electrodes during laser slitting. It supports online spot or full inspection, ensuring slits form precise functional structures. This enhances process consistency and decreases battery safety risks resulting from inaccurate slitting.

Coating Roller Pressed Electrode Embossing

With 0.1μm repeatability accuracy, the SR8020 profiler scans embossed surface bumps on electrodes to control morphology precisely. It measures bump depth and width to verify conformance to design standards, preventing variations that could impact battery performance. The sensor supports inspection speeds up to 800mm/s, ideal for high-speed winding embossing lines.

Post-Weld Defect Detection

The SR7080 profiler outputs brightness and height maps to measure weld mark width, area, and appearance accurately. It locates weld trajectories and assesses defect depth, enabling precise weld quality quantification. This identifies defects such as explosions, cold welds, or weld path shifts efficiently, aiding in the timely removal of defective units and reducing risks to cell performance.

Top Cover Step Gap Inspection

Using the SR8062, the system detects gaps as small as 0.05mm and step heights from 0.25mm. It measures differences in step height and gap after cell pressing through the edge contour and 3D modeling analyses. This delivers accurate dimensional data necessary for top cover welding, preventing defects due to excessive gaps and ensuring sealing integrity.

Top Cover Post-Weld Quality Inspection

The SR8060H performs single-camera front/back or dual-camera scans on the lithium battery top cover welds along its long side, short side, and R-corners. It generates 3D point clouds and brightness images to detect weld defects such as explosions and pits, preventing leakage issues and meeting stringent inspection requirements.

Seal Pin Post-Weld Quality Inspection

The SR8020 collects 3D point clouds and grayscale images with a 5μm resolution on the X-axis for full-dimension morphology examination of complex curved weld areas. It efficiently identifies critical defects, including explosion points, welding pits, pinholes, and broken welds, reducing electrolyte leakage risks and ensuring appearance quality.

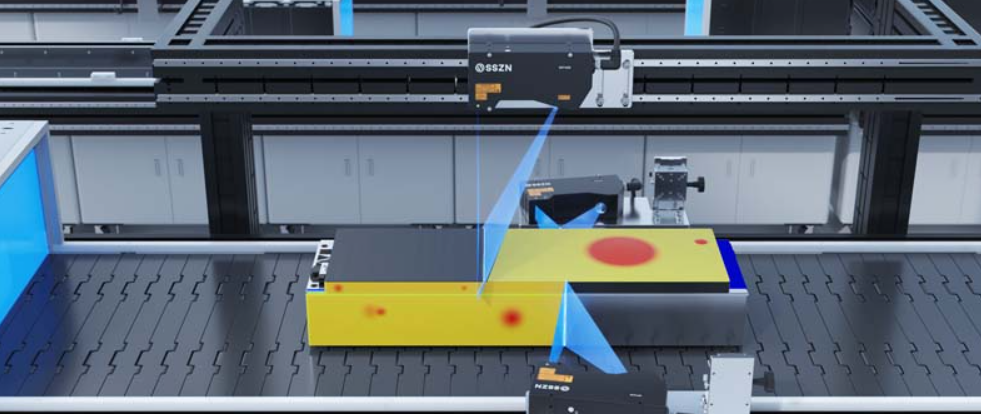

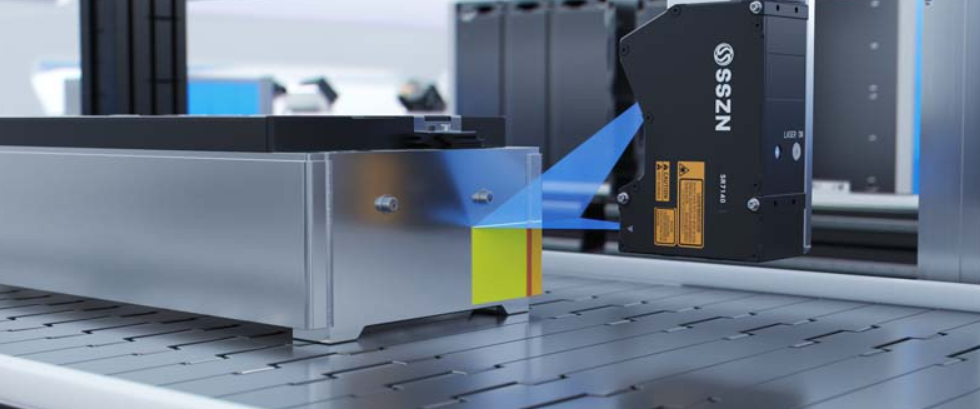

Post-Coating Battery Cell Appearance and Dimension Inspection

The SR7140 detects surface defects on blue films, such as bubbles, wrinkles, and scratches, using criteria of height/depth/width ≥ 0.2mm and wrinkle/scratch length ≥ 2mm. It also measures cell length and width with a 0.3mm tolerance via dual-camera through-beam methods. This ensures the cell’s five sides (excluding top cover) meet process standards, supporting assembly accuracy and safety.

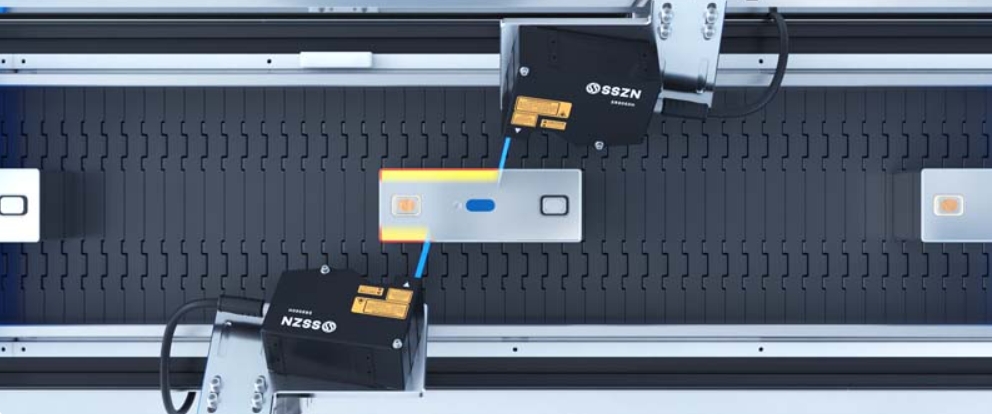

Busbar Post-Weld Quality Inspection

The SR8060 scans busbars to obtain point clouds and grayscale images for detecting gaps between pre-weld busbars and electrodes and post-weld defects. It identifies weld seam contours and defects meeting thresholds of height/depth/width ≥ 0.2mm and diameter ≥ 0.5mm. This ensures electrical connection reliability and mechanical strength for stable circuit operation.

Module Side Seam Post-Weld Quality Inspection

Using the SR7140, comprehensive side seam scans produce point cloud data compared against standard models. It accurately identifies welding defects like porosity, cracks, and incomplete penetration, ensuring weld integrity vital for module structural strength and sealing.

Module Appearance and Dimension Inspection

The SR7240 long side and SR7400 top models employ multi-camera stitching through-beam scanning to inspect the module’s large surfaces and sides. They evaluate flatness, contour abnormalities, and dimensions within tolerances of 0.08mm to 0.1mm. Concurrently, surface defects such as dents and scratches are captured, supporting quality compliance and reliable assembly.

Pack Glue Coating Defect Detection

The SR7080 leverages point cloud analysis and edge recognition to detect discontinuity or irregularity in glue lines. It identifies defects such as glue overflow, breaks, and omissions, providing immediate quality feedback to prevent pack sealing failures and ensure protection.

Pack Appearance Defect Inspection

By utilizing SR5280 top, SR7400 length, and SR7140 profilers, the system captures high-precision point clouds and grayscale images. Intelligent algorithms compare these against standard models to detect pack-level appearance flaws, including scratches, dents, and deformation. It also measures tabs and connector dimensions, guaranteeing adherence to quality standards.

Conclusion

SinceVision’s SR Series encompasses core real-world inspection applications in intelligent lithium battery manufacturing. Through the in-depth deployment of 3D sensor, manufacturers gain full-process precision control spanning electrode production, cell formation, and module and pack assembly. Key stages such as coating and calendering thickness measurement, winding observation, and busbar welding inspection benefit from micrometer-level detection accuracy paired with industrial-grade robustness.

As a global sensor leader, SinceVision has delivered industrial precision measurement solutions to over 10,000 customers worldwide. In the lithium battery sector, its technology advances detection accuracy and efficiency, accelerating the industry’s shift toward high-precision manufacturing.

Looking ahead, SinceVision remains committed to innovation in the new energy field. Its independently developed industrial precision measurement matrix products will continue enabling smarter, more precise inspection tools. Partnering across the supply chain, SinceVision aims to foster a green, efficient, and intelligent lithium battery manufacturing ecosystem that promotes sustainable growth and high-quality development for the new energy industry.

Contact us for demo/sample/consulation at info@sincevision.com

-

Corporate News2025-11-04Get Free Tickets for SPS Germany and Explore SinceVision Industrial Sensors

-

Corporate News2025-10-22SinceVision Sponsors FLUCOME 2025 and Set to Debut Breakthrough AIR Series High-Speed Camera in The Netherlands

-

Corporate News2025-10-20SinceVision to Launch Groundbreaking AIR Series at 6th International Conference on Fluid Flow and Thermal Science (ICFFTS 2025)

-

Industry News2025-10-10Transform PCB Quality Control from Reactive to Proactive with 3D Laser Profiling