Introduction: The Measurement Challenge in Consumer Electronics

Foldable smartphones and tablets are transforming the consumer electronics market, offering users seamless flexibility and portability. At the heart of this innovation lies the foldable screen hinge, a critical component that directly determines product durability, user experience, and overall performance.

However, ensuring the reliability of these hinges is far from simple. Manufacturers face micron-level measurement challenges, where even the smallest deviations in flatness or height difference can compromise device quality. To address these hurdles, SinceVision has developed the SRI7060 Integrated Line Laser 3D Camera, a breakthrough in precision measurement technology that empowers smart manufacturing in the electronics sector.

This case study explores how SinceVision’s technology successfully resolves the three major challenges in hinge measurement and demonstrates its application advantages for high-volume production lines.

The Three Key Challenges in Foldable Screen Hinge Measurement

1. Micron-Level Precision Requirements

Flatness and height difference are the core quality control indicators of foldable hinges. To meet industry standards, the measurement system must deliver repeatability at the micron level. Traditional optical methods often fail to achieve this level of accuracy, especially when dealing with reflective metal surfaces.

2. Complex Structural Measurement

A foldable hinge is not a simple mechanical part. Its multi-layered, reflective, and curved surfaces present serious difficulties for measurement. A reliable system must be able to capture 3D coordinates across multiple feature points simultaneously, reconstruct curved surfaces, and calculate flatness and height differences without compromising precision.

3. Repeatability and Reproducibility (GR&R)

In large-scale production, GR&R (Gauge Repeatability and Reproducibility) is a critical benchmark. High reflection from hinge surfaces often introduces noise and instability, leading to inconsistent data and low GR&R pass rates. For consumer electronics manufacturers, this translates into higher costs, rework, and potential quality risks.

Case Measurement Requirements

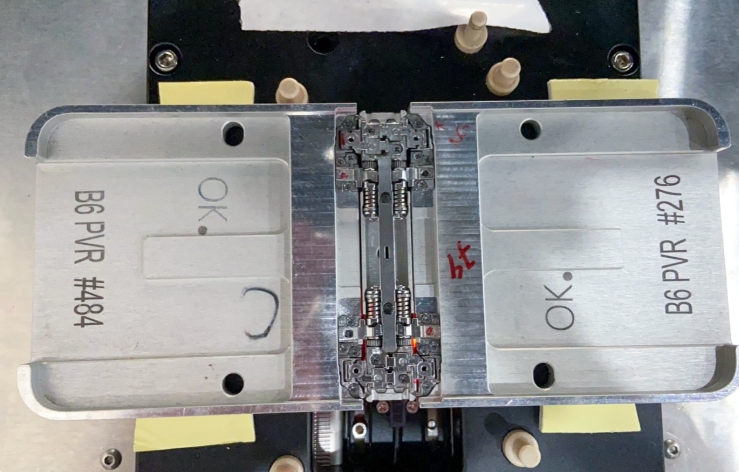

Workpiece: Foldable screen hinge

Size: 10 x 80 x 2 mm

Measurement Focus: Flatness and height difference

Accuracy Requirement: Repeatability within 0.01 mm

The above parameters highlight why traditional vision systems fall short and why an advanced integrated 3D laser profiler is needed for mass production in the consumer electronics industry.

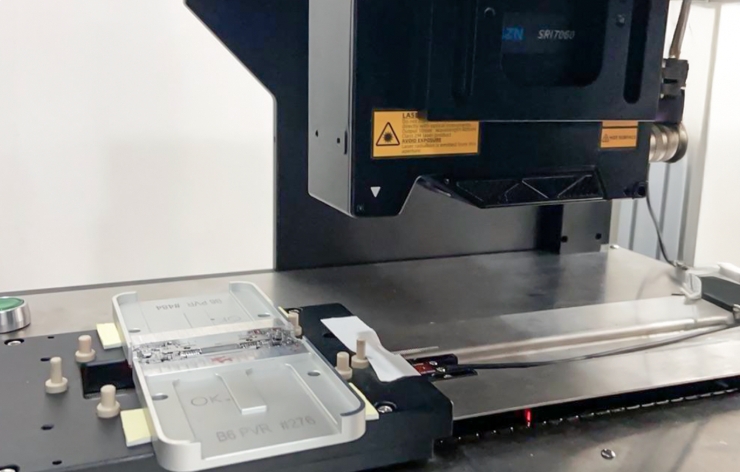

SinceVision’s Integrated 3D Laser Profiler: SRI7060

To overcome these obstacles, SinceVision introduced its flagship product, the SRI7060 Integrated 3D Laser Profiler. This system combines:

1. Precise hardware parameter matching

2. Advanced algorithm optimization

3. Compact, integrated design

Together, these innovations enable manufacturers to perform accurate, repeatable, and efficient measurements of foldable screen hinges, unlocking higher product reliability and improved production efficiency.

Figure: SRI7060 3D laser profiler

1. Precise Hardware Parameter Matching

The SRI7060 profiler is engineered with 33 mm Z-axis range and 49 mm X-axis field of view, enabling one-pass scanning of the entire hinge without repositioning. This significantly reduces cycle time while ensuring comprehensive data capture.

Key Hardware Features:

Scanning Speed: 200 mm/s for high-throughput production.

Laser Source: 405nm high-contrast laser designed for reflective surfaces.

Adaptive Exposure Algorithm: Suppresses glare from metallic components, minimizing noise and maximizing data reliability.

With these specifications, the SRI7060 is perfectly suited for the 3C industry (computer, communication, and consumer electronics) where speed and accuracy are equally essential.

Figure: 3D camera measuring the flatness and height difference of the folding screen hinge

2. Algorithm Optimization for Repeatability

Hardware alone cannot solve the challenge of repeatability. That’s why SinceVision integrated proprietary algorithms into the SRI7060, ensuring stable and consistent measurement results.

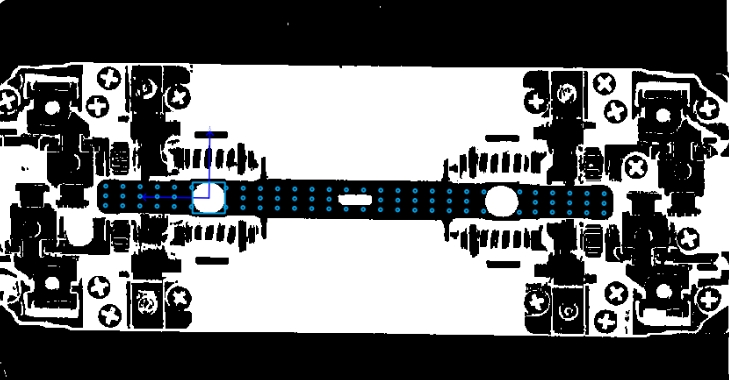

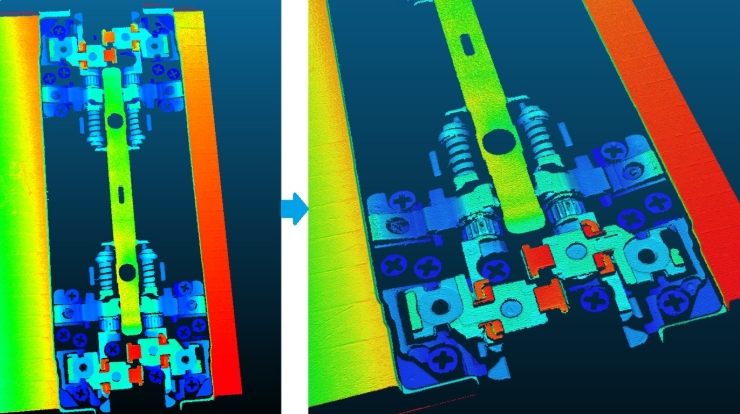

Figure: Region of interest positioning image

Spatial Plane Fitting Algorithm (Least-Squares Method)

The system acquires XYZ coordinates from reference and measurement points. Using least-squares fitting, it calculates the exact distance between each point and the fitted plane. This provides reliable and repeatable flatness and height difference evaluation.

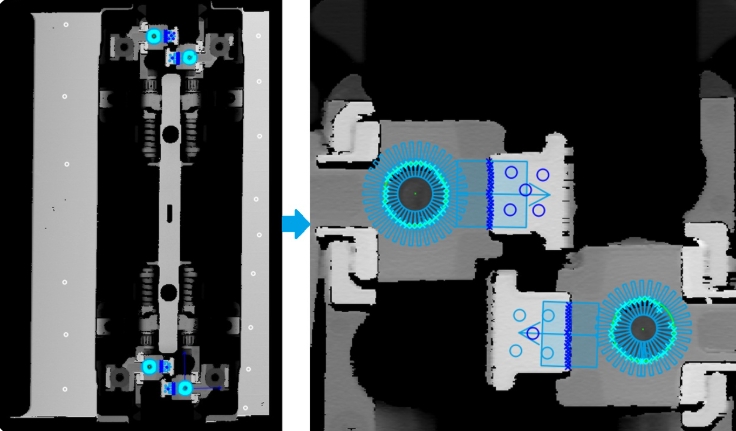

Figure: Baseline ROI positioning image(Left) | Measurement ROI positioning image (Right)

Multi-Dimensional Repeatability Calibration

Built-in temperature compensation and mechanical error correction modules ensure measurement consistency under varying environmental and motion conditions. The fixed-camera and horizontal-product movement setup further reduces external interference.

Proven GR&R Validation

The system underwent 50 rounds of GR&R testing and achieved repeatability accuracy of <0.005 mm (5 μm). This surpasses industry benchmarks and fully meets micron-level quality control standards required in foldable hinge manufacturing.

Note: All results were verified under controlled laboratory conditions. Practical results may vary depending on production environment.

3. Adaptability to Complex Production Lines

Modern electronics factories demand compact and versatile inspection systems. The SRI7060 was designed with this in mind.

Production Line Benefits:

Embedded Installation: The integrated design allows the profiler to fit seamlessly into existing hinge inspection stations without additional space requirements.

Simplified Operation: With one-click setup, scanning, and data analysis, even non-specialist operators can run the system effectively.

Automated Reporting: The system generates 3D point clouds, ROI images, and detailed measurement reports with every inspection cycle. This enables engineers to trace results, adjust processes, and optimize production workflows.

By reducing reliance on expert engineers, the SRI7060 makes advanced 3D measurement accessible for high-speed consumer electronics production lines.

Figure: 3D point cloud effect of folding screen hinge

Real-World Impact: Optimizing Foldable Hinge Reliability

Foldable hinge reliability is one of the biggest technical bottlenecks in foldable smartphones. If hinges fail, the entire product’s lifespan and user trust are compromised.

By providing micron-level flatness and height difference measurements, the SinceVision SRI7060 allows manufacturers to:

a. Optimize stamping and assembly processes.

b. Improve product durability and lifespan.

c. Reduce rework and quality control costs.

d. Ensure consistent product performance in mass production.

Beyond Hinges: Expanding Applications

While this case study focuses on foldable screen hinges, the SRI7060 is equally valuable for other miniature precision components in consumer electronics. The additional applications includes:

i. Camera Modules: Ensuring lens and housing alignment.

ii. Connectors: Detecting micro-deviations that impact conductivity.

iii. Other Micro-Components: Providing quantitative measurements for parts requiring high dimensional accuracy.

This versatility positions SinceVision as a key partner for manufacturers pursuing precision manufacturing upgrades across the consumer electronics industry.

Why SinceVision Leads in Precision Metrology

The SRI7060 is more than just a measurement tool, it is a strategic enabler for smart manufacturing. By integrating hardware, software, and algorithms into one compact solution, SinceVision bridges the gap between R&D laboratories and mass production lines.

Manufacturers gain:

1. Higher yield rates

2. Reduced inspection costs

3. Faster time-to-market

4. Improved product reliability

As the demand for foldable devices grows, SinceVision’s technology ensures that manufacturers can scale production without sacrificing quality.

Conclusion: Driving the Future of Consumer Electronics Manufacturing

Foldable screens represent the next wave of innovation in consumer electronics, but their success depends on the precision of their hinges. Through the SRI7060 Integrated 3D Laser Profiler, SinceVision provides manufacturers with the tools to overcome measurement challenges, achieve micron-level accuracy, and deliver products that meet the highest durability standards.

By extending its capabilities beyond hinges into other precision parts, SinceVision continues to drive smart manufacturing transformation across the industry.

Contact SinceVision today to explore the SRI7060 and discover tailored solutions for your production line.

-

Industry News2025-10-17See Combustion in Ultra-Slow Motion: A 25,000 FPS High-Speed Camera | SinceVision

-

Industry News2025-10-174 Key Lithium Battery Tests Captured by SinceVision SH6 Series High-Speed Camera

-

Industry News2025-10-10Transform PCB Quality Control from Reactive to Proactive with 3D Laser Profiling

-

Industry News2025-09-30Precision in Power Electronics: SinceVision SR8060 3D Laser Profiler for IGBT Heat Dissipation Module Inspection