In the lithium battery industry, safety and reliability are non-negotiable. Every battery must handle real-world challenges. This includes physical impacts and thermal stress. These factors are key to safe performance in electric vehicles and energy storage systems.

Engineers use high-speed cameras to grasp these complex processes. These tools can capture thousands of frames each second. These cameras capture quick events that we can't see. They give us important insights into how batteries react under stress.

This article looks at four important lithium battery testing uses for SinceVision high-speed cameras: drop testing, cell winding fault analysis, laser welding, and acupuncture safety testing. Each section shows the industry challenges. It also explains how SinceVision’s technology helps overcome them.

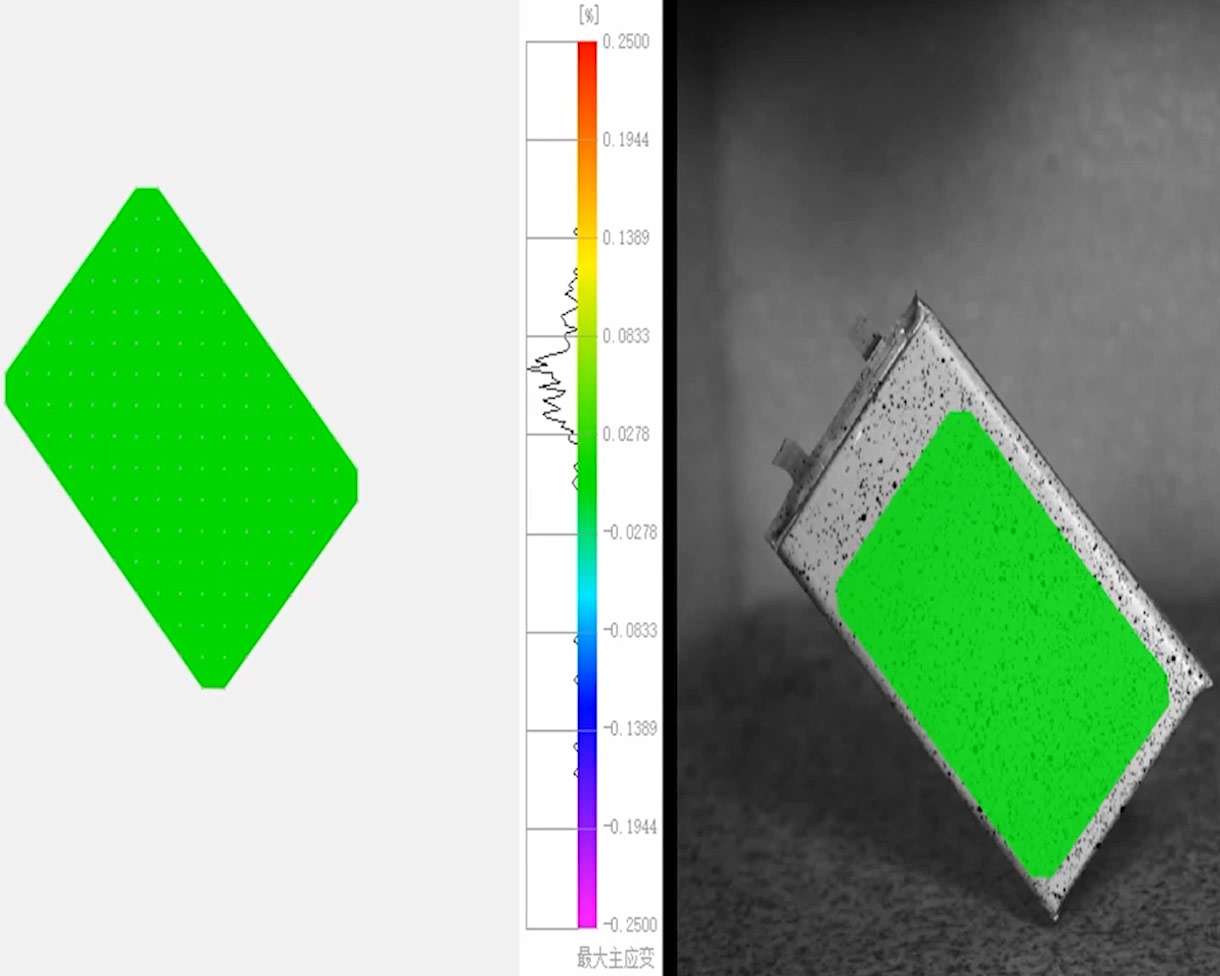

Application 1: Lithium Battery Drop Testing

The Industry Challenge

Drop testing checks how durable and safe lithium batteries are for EVs and portable devices. However, several technical issues make this test difficult to execute effectively:

1. Traditional contact-based methods are labor-intensive and lack multi-point, full-field precision.

2. Capturing dynamic impacts and motion trajectories during drop tests is complex and time-sensitive.

3. Data losses occur during critical moments due to system delays or insufficient storage.

These challenges make it tough for engineers to gather and analyze accurate impact data. As a result, safety evaluations can be incomplete.

SinceVision Solution: SH6-113 High-Speed Camera

The SinceVision SH6-113 high-speed camera offers a precise, non-contact way to test drops in lithium batteries.

a. 13,800 FPS at 1280×1024 resolution captures each millisecond of the drop impact. This allows for detailed motion and deformation analysis.

b. Full-field, multi-point measurement tracks the whole battery surface. It uses trajectory algorithms for non-contact monitoring.

c. Up to 20TB storage and 160Gbps bandwidth, allows continuous high-speed recording without data loss during critical moments.

d. Researchers can now see the full drop impact. This helps improve product safety checks and makes tests more repeatable.

Application 2: Analyzing Lithium Battery Cell Winding Faults

The Industry Challenge

During winding, keeping the right tension and alignment is crucial. This ensures good battery performance and safety. Faults in winding can lead to internal short circuits or capacity loss. Yet traditional monitoring systems struggle with:

1. Data Overload: Massive data from production lines makes real-time fault detection difficult.

2. Inefficiency: Manual inspection slows down analysis and process optimization.

3. Missed Insights: Subtle winding deviations often go undetected with standard-speed cameras.

SinceVision Solution: SH6-502 High-Speed Camera

The SinceVision SH6-502 offers a clear view of fast-moving cell winding. This helps engineers spot and analyze defects in real time.

a. High frame rate and wide field of view capture every detail of winding behavior and tension changes.

b. Micron-level precision detects micro faults such as film slippage, misalignment, and edge folds.

c. Flexible integration connects easily with production lines and analysis software. This helps optimize processes efficiently.

SinceVision’s SH6-502 camera records the winding sequence quickly. This helps spot process issues before they cause expensive failures or safety risks.

Application 3: Optimizing Laser Welding Technology

The Industry Challenge

Laser welding is critical for connecting battery tabs and modules with high precision. The process creates a very bright light. This often causes overexposure, which traditional cameras can't manage. This makes it hard to see the molten pool, spatter, and weld formation in real time. These factors are key to achieving strong and consistent welds.

SinceVision Solution: SH6-207 High-Speed Camera

The SinceVision SH6-207 is built for the tough conditions of high-intensity welding.

a) High dynamic range imaging reduces brightness overexposure. This helps us clearly see how molten metal behaves.

b) A high frame rate combined with high resolution captures weld formation, spatter, and material flow dynamics with precision.

c) Adaptive exposure control automatically adjusts to extreme lighting conditions, which ensures that images remain clear and consistent.

The SH6-207 helps engineers analyze each step of the welding process. This boosts weld quality and ensures steady performance in large-scale battery production.

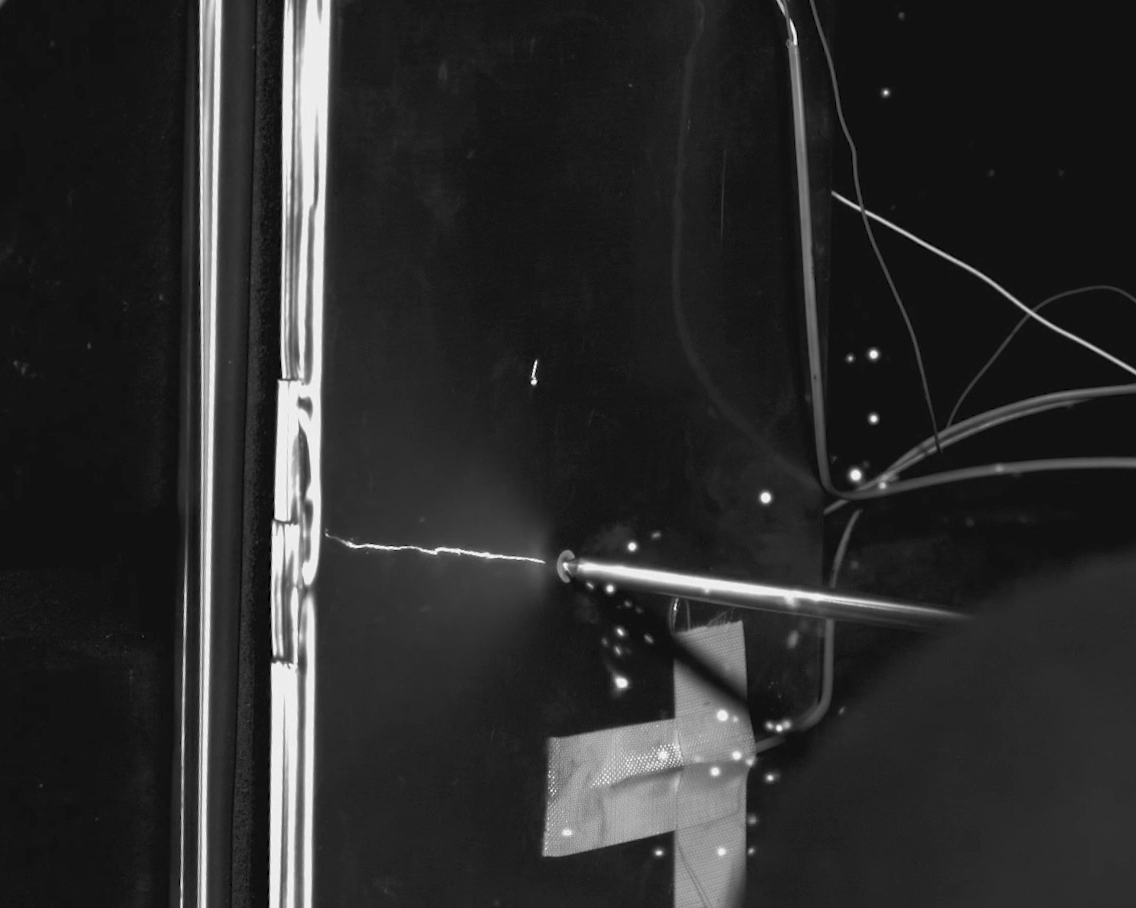

Application 4: Capturing Battery Acupuncture Test Reactions

The Industry Challenge

The acupuncture test mimics severe failure by puncturing the battery. This helps us study how the battery reacts during thermal runaway. These tests involve quick, violent reactions. You’ll see smoke, sparks, and explosions, all happening in milliseconds. Traditional cameras struggle to capture brief events with clarity. This limits our ability to analyze failure mechanisms and safety responses.

SinceVision Solution: SH6-204 High-Speed Camera

The SinceVision SH6-204 provides clear images and fast performance. It's ideal for safety-critical tests like battery acupuncture.

a. High resolution and ultra-fast frame rate capture the full sequence of puncture, short circuit, and explosion in detail.

b. Thermal and visual synchronization enables correlation between surface reactions and internal events.

c. Reliable data capture ensures continuous recording of rapid reactions for accurate cause-and-effect analysis.

The SH6-204 shows the full visual timeline of battery failure. This helps research safer battery materials, structures, and protective designs.

Conclusion

High-speed cameras are essential in lithium battery manufacturing and safety research. They play a key role in drop testing, cell winding, laser welding, and acupuncture testing. They help engineers see, study, and grasp high-speed events that shape battery performance and reliability.

SinceVision’s SH6 Series provides a complete imaging solution for every stage of battery testing. It ensures accurate data. It boosts quality control. Also, it enhances safety for electric vehicles and energy storage systems.

As lithium battery technology evolves, advanced high-speed imaging will stay key. It helps manufacturers create safer, more reliable, and better-performing batteries for the future.

-

Corporate News2025-01-09The All-New SinceVision Smart Series High-Speed Camera: Precision, Innovation, and Ultra Performance

-

Industry News2025-04-17How High-Speed Cameras Work and What They're Used For

-

Industry News2025-04-222000FPS High-Speed Camera Captures the Dynamics of Falling Droplets

-

Industry News2025-06-06How SinceVision's SH6-113 High-Speed Camera Captures Invisible Cavitation Phenomena

-

Industry News2025-06-10SHS Series High-Speed Camera Captures the Full Ice Fracture Process (-20°C) at 2250FPS

-

Corporate News2025-09-24SinceVision Strengthens Global Reach with Supportive Membership in Japan Industrial Imaging Association (JIIA)