In the fast-paced consumer electronics manufacturing industry, glue quality inspection has always been a critical challenge. Precision, speed, and efficiency are non-negotiable. Yet, traditional inspection methods have consistently fallen short.

That’s where the SinceVision SRI8020 integrated 3D laser profiler changes the game. It delivers micron-level accuracy, real-time defect detection, and high-speed performance designed for today’s advanced production lines.

Let’s break down the pain points, the solution, and why this technology is a must-have for manufacturers who want to stay competitive.

Pain Points in Consumer Electronics Glue Quality Inspection

Before we get to the solution, let’s explore the challenges:

2D vision is outdated: It can’t deliver micron-level measurements for glue height, collapse, or other critical 3D parameters.

Fast production cycles demand speed: Consumer electronics manufacturing lines move quickly, and old systems can’t keep up.

Inefficient inspections cost money: False positives, missed defects, and slow checks drag down throughput.

If these sound familiar, you’re not alone. But the answer is here.

SinceVision Sensor Solution

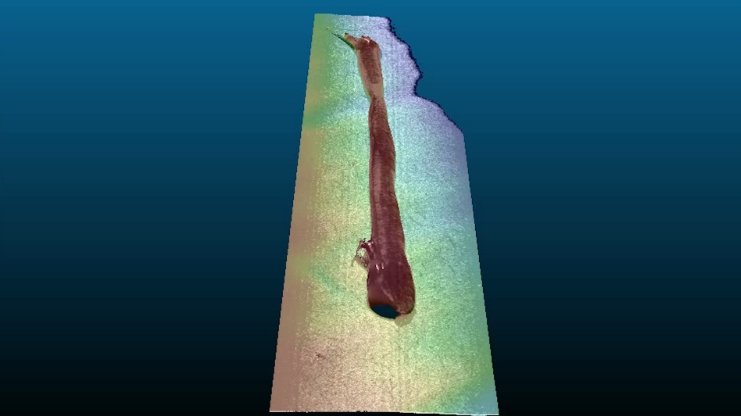

The SRI8020 sensor is designed to solve these exact problems. After glue dispensing, it performs a high-speed scan that outputs:

ØGlue width

ØGlue height

ØFull 3D contour data

This information is compared against your process specs in real-time, with automatic defect marking. The result? Higher accuracy, faster feedback, and less waste.

1. Non-Contact 3D Scanning Technology

Using laser triangulation, the system captures dense 3D point cloud data of glue paths at high speed. In just one scan, you get glue width, glue height, and a full 3D profile. No risk of damaging sensitive parts or uncured adhesives only reliable, non-contact precision.

2. Intelligent Algorithm for Closed-Loop Quality

A deep-learning defect recognition model automatically detects issues like overflow, breaks, or misalignment. Even better, the system sends feedback directly to the dispenser, dynamically correcting process parameters. That’s a closed-loop system in action.

3. High-Speed Synchronized Acquisition

With scanning speeds from 3,200 to 67,000 Hz, the SRI8020 handles full-area glue inspections in milliseconds. It’s built for the rapid pace of consumer electronics production lines, ensuring no slowdown in throughput.

SRI8020 3D Laser Profiler Advantages

1. Micron-Level Ultra-High Precision

With 0.1 μm repeatability, the SRI8020 goes far beyond traditional inspection methods. The benefit? Improved product consistency, reduced risk, and stronger bonding and sealing reliability.

2. Strong Material & Scenario Compatibility

Whether adhesives are transparent, reflective, or varied in properties, the SRI8020 is built to handle it all. This versatility gives manufacturers greater flexibility in material selection.

3. Enhanced Production Efficiency

Compared to manual inspection and caliper measurements, the SRI8020 drastically cuts detection time. It’s the perfect fit for miniaturized, high-precision consumer electronics products like smartphones, wearables, earbuds, and precision connectors.

Why the SRI8020 Matters for the Future of consumer electronics Manufacturing

The consumer electronics industry is moving toward miniaturization, precision, and high reliability. Meeting these demands requires advanced inspection solutions that keep up with innovation. The SinceVision SRI8020 3D laser profiler delivers:

ØMicron-level accuracy

ØMillisecond-level response

ØAll-material compatibility

This sensor helps manufacturers break through quality bottlenecks and capture new market opportunities.

Contact SinceVision today to start your journey toward smarter, faster, and more reliable glue quality inspection in consumer electronics manufacturing.

-

Industry News2025-12-15Solving Measurement Challenges in Opaque and Semi-Transparent Glue Inspection with SinceVision 3D Laser Profiler

-

Industry News2025-12-05Machine Vision Sensor Solutions in Automotive Manufacturing | SinceVision Application Cases

-

Corporate News2025-12-02SinceVision to Exhibit Advanced Imaging and Sensing Technologies at SPIE VISION TECH 2026

-

Corporate News2025-11-17SinceVision Launches New Back-Illuminated Cooled sCMOS Camera Series for Ultra-Low-Light Scientific Imaging