Maintaining PCB board flatness and detecting height differences are critical for consumer electronics manufacturing. A warped PCB board can cause assembly problems, poor soldering, or even complete device failure.

Even small height differences between components can create misalignment. This affects product performance and reduces durability. Manual checks or 2D inspection tools often lack the precision and speed required for today’s high-density PCB designs.

Challenges in PCB Inspection

In modern production lines, PCBs are becoming smaller and more complex. Component density is increasing, making inspection more difficult. Any warping or unevenness can impact electrical connections and product life span. Manufacturers need accurate, fast, and non-contact inspection methods to maintain quality.

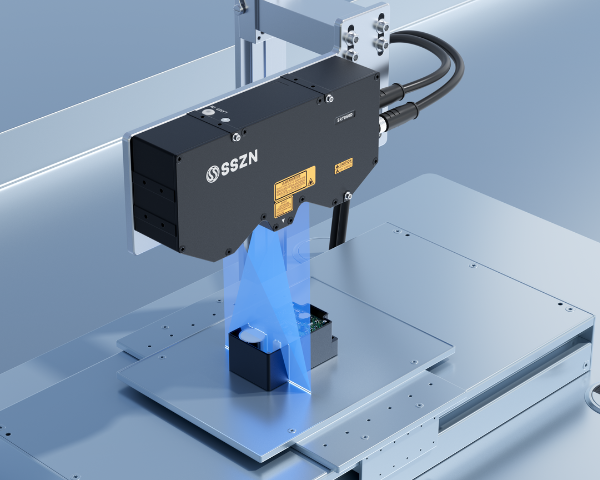

SinceVision SR7060D 3D Laser Profiler Solution

The SinceVision SR7060D 3D laser profiler is designed to meet these inspection demands. It combines high accuracy, fast scanning, and non-contact measurement to ensure PCB quality.

Key Advantages:

a. Ultra-High Accuracy: Measures board flatness and component height at the micrometer level. Perfect for high-density PCB designs.

b. Rapid Scanning Speed: Inspects PCBs in real time, matching high-speed production without losing accuracy.

c. Non-Contact Inspection: Prevents damage to sensitive PCB surfaces while maintaining consistent measurement quality.

Technical Specifications:

Reference distance (CD): 57 mm

Repetition accuracy Z-axis (height): 0.2 μm

Linearity Z-axis (height): ±0.05% F.S.

X-axis contour points: 3200

Scanning speed: up to 10,000 Hz

Why Use a 3D Laser Profiler for PCB Inspection?

A 3D laser profiler or 3D sensor provides precise surface data in three dimensions. This ensures accurate detection of warping and height variation. The 3D sensor captures detailed surface profiles without touching the board, protecting delicate circuits.

Using the SR7060D 3D laser profiler allows manufacturers to achieve consistent quality, reduce defects, and improve production efficiency.

For sales inquiries, samples, or product demonstrations, please contact us: info@sincevision.com

-

Industry News2025-09-30Precision in Power Electronics: SinceVision SR8060 3D Laser Profiler for IGBT Heat Dissipation Module Inspection

-

Corporate News2025-09-24SinceVision Strengthens Global Reach with Supportive Membership in Japan Industrial Imaging Association (JIIA)

-

Industry News2025-09-29SinceVision to Showcase Industrial Vision Sensors at SPS Germany 2025 Machine Vision Exhibition

-

Industry News2025-09-02Case Study: How SinceVision's Integrated 3D Laser Profiler Solves Precision Measurement Challenges in Foldable Screen Hinges