In the electronics manufacturing industry, precision defines success. Even the smallest defect can compromise performance and reliability. Missing PCB components, like capacitors and inductors, are common quality problems. They can also be quite damaging. One missing part can cause the device to fail completely. This can lead to expensive recalls and damage to the brand’s reputation.

Manufacturers want zero-defect production. So, traditional 2D inspection and manual checks aren't enough anymore. They fail to capture height variations or detect low-profile components with consistency. Manufacturers must find a solution that goes beyond reactive quality control. They need a way to spot problems before they escalate to meet modern production demands.

SinceVision’s SRI8060 Integrated 3D laser profiler delivers exactly that. It changes inspection from manual checks to automated, data-driven detection. This ensures perfect PCB assembly and steady product quality.

Critical Challenge: Costly Consequences of Missing PCB Components

In high-volume PCB manufacturing, every second and every defect count. Though common, manual inspection methods face limitations due to human fatigue and inconsistency. Operators may miss small or low-profile components, especially on crowded boards.

Traditional 2D AOI (Automated Optical Inspection) systems also have inherent limitations. They offer surface-level imaging but don’t measure height. This makes it hard to find missing parts or components hidden under solder paste. Some defects can go unnoticed until later assembly stages. By then, fixing them is much more costly.

These inefficiencies lead to higher quality costs, production delays, and waste from rework or scrap. Worse, missing parts can go unnoticed. This can cause product failures in the field. As a result, it harms customer trust and damages brand reputation. The need for accurate, inline, and automated quality control has never been greater.

SinceVision Solution: High-Precision, Inline Missing Component Detection

The SinceVision SRI8060 Integrated 3D Laser Profiler solves these problems. It provides quick and precise 3D measurements. It’s made for inline inspection. This way, every PCB meets top quality standards before it leaves the line.

Technical Specifications:

Model: SRI8060

Measurement Range: 18 mm (Z-axis)

Repeatability: 0.2 μm (Z-axis)

Linearity Accuracy: ±0.02% F.S. (Z-axis)

Scanning Speed: 3,200–67,000 Hz

The SRI8060 is designed for industrial automation. It offers micron-level precision and processes data in real time. This allows for ongoing quality assurance while keeping production running smoothly.

How the SRI8060 Ensures Flawless PCBs: A Three-Step Process

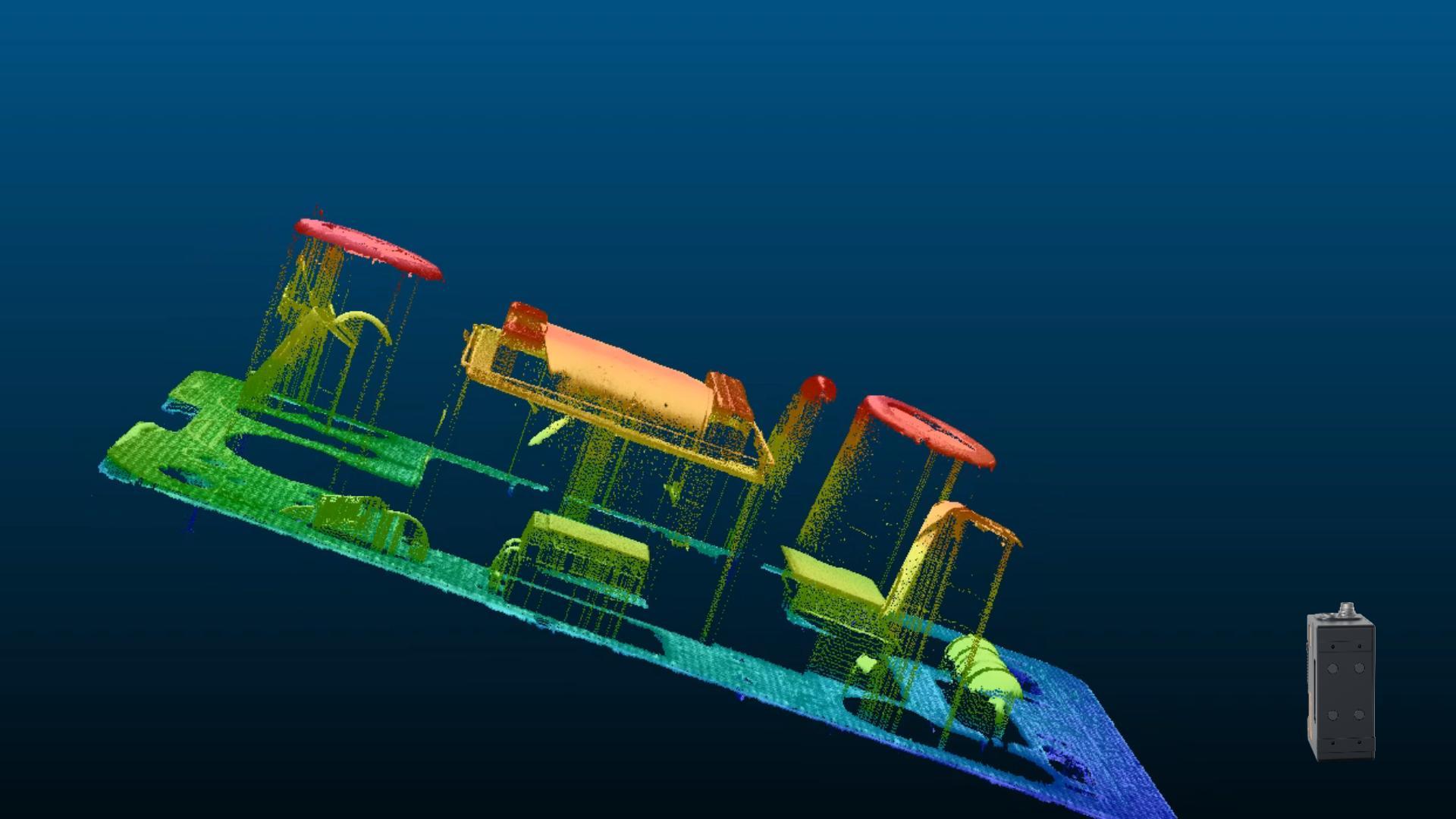

1. Precise 3D Topography Reconstruction: SRI8060 3D Laser Profiler scans the PCB surface. It captures millions of data points to create a detailed 3D topography. This point cloud data shows even tiny height changes. It lets us recreate the board surface accurately, down to sub-micron levels.

2. Smart Comparison to a Golden Template: The system checks each scan against a standard height template of a reference PCB. Any deviation, like a missing capacitor, inductor, or chip, is quickly spotted. This happens because its expected height profile is absent. This intelligent height-based analysis eliminates false detections common in 2D inspection.

3. Real-Time Feedback for Proactive Prevention: Inspection results go straight to the production line control system. This allows for quick alarms or automated sorting actions. Defective boards are set aside before the next step. This stops quality issues from spreading later. This real-time integration helps manufacturers stay proactive. They can keep production going smoothly without any issues.

Key Benefits: Driving Efficiency and Reliability in Your Production Line

A. Proactive Defect Prevention: SRI8060 helps catch missing components quickly. This moves quality control from fixing problems to preventing them before they start. It catches defects early. This reduces rework and scrap. It also keeps yield rates consistent.

B. Data-Driven Optimization: SRI8060 provides detailed inspection data. You can look at this data to find common problems, enhance processes, and change production settings. Manufacturers can use this insight to improve continuously and lower quality costs.

C. Unmatched Integration and Efficiency: SRI Series has an all-in-one design. It combines the sensor head and controller into one compact unit. This cuts installation space by up to 65%. It also simplifies wiring and boosts system reliability. The profiler easily connects to current production line control systems. This cuts setup time and boosts uptime.

Why Choose SinceVision's SRI Series 3D Laser Profilers?

SinceVision’s SRI Series 3D laser profilers meet the tough needs of today’s electronics manufacturing. They provide a scalable solution for automated inspection. This combines precision, speed, and integration. It works well in PCB, semiconductor, and electronic assembly applications.

SinceVision has years of experience in laser measurement sensors and industrial automation. We keep innovating. Their solutions boost manufacturing reliability and intelligence. The SRI Series is trusted by manufacturers worldwide. It detects missing PCB components and measures complex surface geometries. Its consistency and performance stand out.

Conclusion

As electronic devices get smaller and more complex, precise PCB quality control is crucial. The SinceVision SRI8060 Integrated 3D Laser Profiler helps manufacturers by detecting missing components. It offers the accuracy, speed, and intelligence needed to prevent costly failures.

It helps manufacturers achieve zero defects by combining accurate measurements with smooth production line integration. This leads to lower quality costs and boosts market competitiveness.

Contact SinceVision’s experts today. Learn how the SRI8060 3D Laser Profiler can boost your quality assurance. Transform your production line into a proactive, data-driven operation.

-

Industry News2024-08-19Samsung's Solid-State Battery: 965 km Range & 9-Minute Charge Revolutionize EVs

-

Industry News2024-10-12How is machine vision revolutionizing electric vehicle production?

-

Industry News2025-08-14PCB Board Flatness and Height Difference Inspection with SinceVision 3D Laser Profiler

-

Industry News2025-09-18Lithium Battery Inspection: How SinceVision SR Series 3D Laser Profilers Address Critical Quality Control Challenges

-

Industry News2025-09-29SinceVision to Showcase Industrial Vision Sensors at SPS Germany 2025 Machine Vision Exhibition

-

Corporate News2025-09-24SinceVision Strengthens Global Reach with Supportive Membership in Japan Industrial Imaging Association (JIIA)

-

Industry News2025-09-30Precision in Power Electronics: SinceVision SR8060 3D Laser Profiler for IGBT Heat Dissipation Module Inspection