Height Difference Inspection for Automotive Metal Parts with SinceVision 3D Laser Profiler

Industry pain points and demands

In the automotive sector, precision in metal parts manufacturing is critical to ensure structural integrity and optimal performance. SinceVision’s SR7400 3D Laser Profiler provides an advanced solution for inspecting height differences in metal parts, meeting stringent industry standards for accuracy and quality.

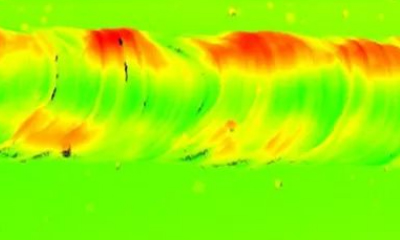

Physical Picture or Imaging Effect Picture

SinceVision Solution: SR7400 3D Laser Profiler

01High-Precision Measurement: The SR7400 3D Laser Profiler delivers exceptional repeatability of 0.04mm, ensuring reliable results for even the most demanding height difference inspections.

02Versatile Application: Designed specifically for automotive metal parts, it supports a variety of component types and dimensions.

03Enhanced Efficiency: The profiler’s cutting-edge 3D laser technology enables rapid and accurate inspections, reducing downtime and enhancing production workflows.

Camera Selection

| Model number | SR7400 | |||

| Reference distance (CD) | 400mm | |||

| Measuring range | Z-axis height (FS) | 200mm | ||

| X-axis width | Near side | 180mm | ||

| Reference distance | 220mm | |||

| Distal end | 280mm | |||

| Light source | Light source wavelength | 405nm blue light | ||

| Laser class | 2M | |||

| Laser output power | 10mW | |||

| Repetition accuracy | Z-axis (height) | 5μm | ||

| X-axis (width) | 20μm | |||

| linearity | Z-axis (height) | ±0.05% F.S. | ||

| Contour data interval | X-axis (width) | 90μm | ||

| X-axis contour points | 3200 | |||

| Reflection Angle (°) | 17 | |||

| Scanning speed (Hz) | 2500 ~ 8000 | |||

| Dimension (mm) | 189.5×93×48 | |||

| Weight (g) | 840 | |||

| Temperature characteristic | 0.02% F.S./℃ | |||

| Encoder input | Single-ended, differential coders are supported | |||

| Input/output | One 100Base-TX/1000Base-T Ethernet interface | |||

| Operation Temperature | 0~50℃ | |||

| Storage Temperature | -20~70℃ | |||

| Working Humidity | 35% to 85% without condensation | |||

| ESD Protection | Contact discharge 4kV, air discharge 8kV, in accordance with IEC 61000-4-2 standards | |||

| EFT protection | Power port 2kV/5 or 100kHz, signal port 1kV/5 or 100kHz, in accordance with IEC 61000-4-4 standards | |||

| Impact | 50Gs/3ms per axis, in accordance with IEC 68-2-27 Ea standard | |||

| Vibration | 10Gs(10-500Hz)符合 IEC 68-2-6 Fc标准标准 | |||

| degrees of protection provided by enclosure | IP67, in accordance with IEC 60529 standard | |||