Glue Dispensing Detection for String Welding Machines in Battery Cell Testing

After the battery cells are manufactured, battery cells with the same or similar performance can be connected in series through a string welding machine. During this process, glue dispensing operations will be performed at the main grid electrode and the fine grid electrode. The glue height needs to be tested to ensure that the glue completely covers the main grid to fix it.

· Glue Height Accuracy: Improper glue height may lead to incomplete coverage of the main grid, resulting in weak fixation and compromised electrical connections.

· Precision Challenges: Traditional inspection methods often lack the resolution and speed required to assess the glue’s top surface and contour details accurately.

· High-Volume Production: Efficient and stable detection systems are necessary to meet the demands of large-scale photovoltaic manufacturing.

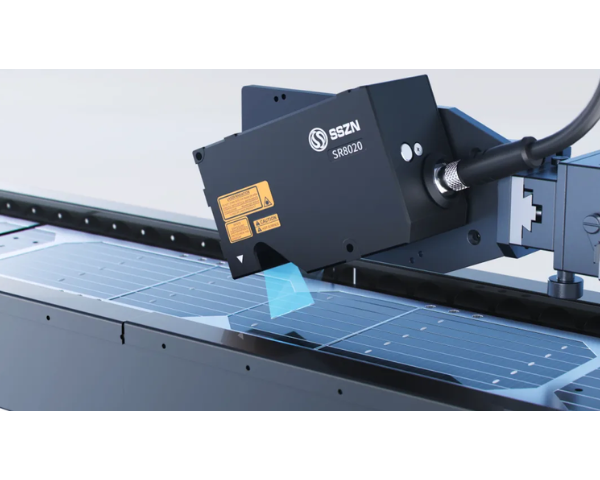

SinceVision Solution: SR8020 3D Laser Profiler

Camera Selection

| Model number | SR8020 | |||

| Reference distance (CD) | 23mm | |||

| Measuring range | Z-axis height (FS) | 5.2mm | ||

| X-axis width | Near side | 13mm | ||

| Reference distance | 14.5mm | |||

| Remote side | 16mm | |||

| Light source | Light source wavelength | 405nm blue light | ||

| Laser class | 2M | |||

| Laser output power | 10mW | |||

| Repetition accuracy | Z-axis (height) | 0.15μm | ||

| X-axis (width) | 1.5μm | |||

| linearity | Z-axis (height) | ±0.02% of F.S. | ||

| Contour data interval | X-axis (width) | 5μm | ||

| X-axis contour points | 3200 | |||

| Reflection Angle (°) | 41.5 | |||

| Scanning speed (Hz) | 3200 ~ 67000 | |||

| Dimension (mm) | 125.5×82×55 | |||

| Weight (g) | 650 | |||

| Temperature characteristic | 0.02% F.S./℃ | |||

| Encoder input | Single-ended, differential encoder is supported | |||

| Input/output | One 100Base-TX/1000Base-T Ethernet interface | |||

| Operation Temperature | 0~50℃ | |||

| Storage Temperature | -20~70℃ | |||

| Working Humidity | 35% to 85% without condensation | |||

| ESD Protection | Contact discharge 4kV, air discharge 8kV, in accordance with IEC 61000-4-2 standards | |||

| EFT protection | Power port 2kV/5 or 100kHz, signal port 1kV/5 or 100kHz, in accordance with IEC 61000-4-4 standards | |||

| Impact | 50Gs/3ms per axis, in accordance with IEC 68-2-27 Ea standard | |||

| Vibration | 10Gs (10-500Hz), compliant with IEC 68-2-6 Fc standard | |||

| degrees of protection provided by enclosure | IP67, in accordance with IEC 60529 standard | |||