Edge Detection in Food and Packaging Industry with SinceVision 3D Laser Profiler

Industry pain points and demands

In the food industry, ensuring precise edge detection is vital for packaging alignment, portion control, and product quality. Irregular edges or misalignments can lead to production inefficiencies, waste, and compromised safety standards. Traditional detection methods often lack the speed and precision required for high-volume operations, making advanced technology essential.

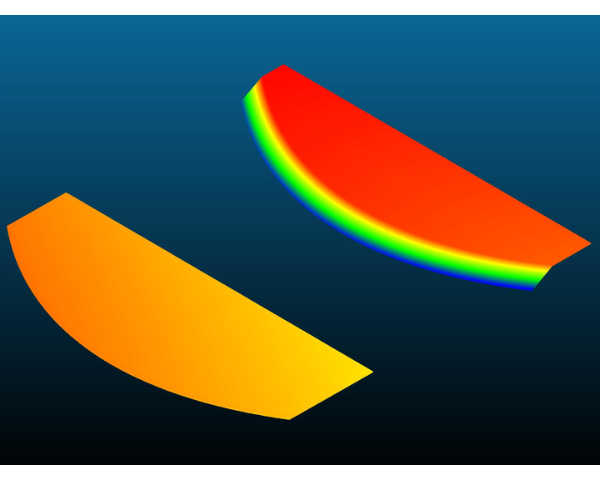

Physical Picture or Imaging Effect Picture

SinceVision Solution: SR8020 3D Laser Profiler

01High Sampling Frequency: With a sampling frequency ranging from 3.2KHz to 67KHz, SinceVision’s SR8020 3D Laser Profiler offers high-speed, precise edge detection, ensuring superior quality control in food production processes.

02Wide Compatibility: Easily integrates into diverse production lines, enhancing operational efficiency.

03Precise Detection: Identifies even minor irregularities in product edges, reducing waste and ensuring consistency.

Camera Selection

| Model number | SR8020 | |||

| Reference distance (CD) | 23mm | |||

| Measuring range | Z-axis height (FS) | 5.2mm | ||

| X-axis width | Near side | 13mm | ||

| Reference distance | 14.5mm | |||

| Remote side | 16mm | |||

| Light source | Light source wavelength | 405nm blue light | ||

| Laser class | 2M | |||

| Laser output power | 10mW | |||

| Repetition accuracy | Z-axis (height) | 0.15μm | ||

| X-axis (width) | 1.5μm | |||

| linearity | Z-axis (height) | ±0.02% of F.S. | ||

| Contour data interval | X-axis (width) | 5μm | ||

| X-axis contour points | 3200 | |||

| Reflection Angle (°) | 41.5 | |||

| Scanning speed (Hz) | 3200 ~ 67000 | |||

| Dimension (mm) | 125.5×82×55 | |||

| Weight (g) | 650 | |||

| Temperature characteristic | 0.02% F.S./℃ | |||

| Encoder input | Single-ended, differential encoder is supported | |||

| Input/output | One 100Base-TX/1000Base-T Ethernet interface | |||

| Operation Temperature | 0~50℃ | |||

| Storage Temperature | -20~70℃ | |||

| Working Humidity | 35% to 85% without condensation | |||

| ESD Protection | Contact discharge 4kV, air discharge 8kV, in accordance with IEC 61000-4-2 standards | |||

| EFT protection | Power port 2kV/5 or 100kHz, signal port 1kV/5 or 100kHz, in accordance with IEC 61000-4-4 standards | |||

| Impact | 50Gs/3ms per axis, in accordance with IEC 68-2-27 Ea standard | |||

| Vibration | 10Gs (10-500Hz), compliant with IEC 68-2-6 Fc standard | |||

| degrees of protection provided by enclosure | IP67, in accordance with IEC 60529 standard | |||