Pantograph Carbon Strip Detection in Railway Industry with SinceVision 3D Laser Profiler

Industry pain points and demands

The pantograph’s carbon strip, which ensures efficient electrical contact between trains and overhead lines, is prone to wear and damage due to continuous friction and exposure to environmental elements. Undetected wear can lead to energy loss, equipment damage, and costly downtime. Traditional inspection methods often fail to identify subtle defects in time, compromising train performance and safety.

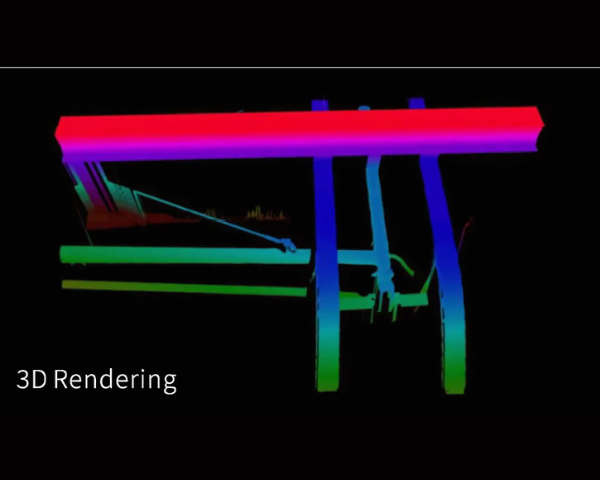

SinceVision Solution: SR5320 3D Laser Profiler

01Efficient Inspection: Ultra-fast scanning at 67K/s captures detailed 3D profiles, enabling quick and thorough fastener analysis.

02 Comprehensive Coverage: Wide measurement range of 440mm x 640mm scans multiple fasteners in one pass with exceptional precision at 3200 X-axis points.

03Durable Design: Engineered to withstand challenging railway environments, ensuring reliable performance in high-demand applications.

Camera Selection

| Model number | SR5320 | |||

| Reference distance (CD) | 500mm | |||

| Measuring range | Z-axis height (FS) | 510mm | ||

| X-axis width | Near side | 360mm | ||

| Reference distance | 470mm | |||

| Remote side | 640mm | |||

| Light source | Light source wavelength | 450nm blue light | ||

| Laser class | 3R | |||

| Laser output power | 50mW | |||

| Repetition accuracy | Z-axis (height) | 7.5μm | ||

| X-axis (width) | 50μm | |||

| linearity | Z-axis (height) | ±0.02% of F.S. | ||

| Contour data interval | X-axis (width) | 200μm | ||

| X-axis contour points | 3200 | |||

| Reflection Angle (°) | 35 | |||

| Scanning speed (Hz) | 2500 ~ 67000 | |||

| Dimension (mm) | 460×92.5×62 | |||

| Weight (g) | 1900 | |||

| Temperature characteristic | 0.02% F.S./℃ | |||

| Encoder input | Single-ended, differential encoder is supported | |||

| Input/output | One 100Base-TX/1000Base-T Ethernet interface | |||

| Operation Temperature | 0~50℃ | |||

| Storage Temperature | -20~70℃ | |||

| Working Humidity | 35% to 85% without condensation | |||

| ESD Protection | Contact discharge 4kV, air discharge 8kV, in accordance with IEC 61000-4-2 standards | |||

| EFT protection | Power port 2kV/5 or 100kHz, signal port 1kV/5 or 100kHz, in accordance with IEC 61000-4-4 standards | |||

| Impact | 50Gs/3ms per axis, in accordance with IEC 68-2-27 Ea standard | |||

| Vibration | 10Gs (10-500Hz), compliant with IEC 68-2-6 Fc standard | |||

| degrees of protection provided by enclosure | IP67, in accordance with IEC 60529 standard | |||