Wheel Set Detection of Trains with SinceVision 3D Laser Profiler

Industry pain points and demands

Wheel sets are critical components in train safety and performance. Even minor defects in wheel geometry, such as flat spots, ovalization, or wear, can lead to operational instability, noise, and accelerated rail degradation. Detecting these issues during inspections requires highly precise and reliable equipment to ensure the safety and longevity of both the wheel sets and the railway infrastructure. Traditional inspection methods often lack the precision and speed necessary for modern railway maintenance needs, making advanced technology a necessity.

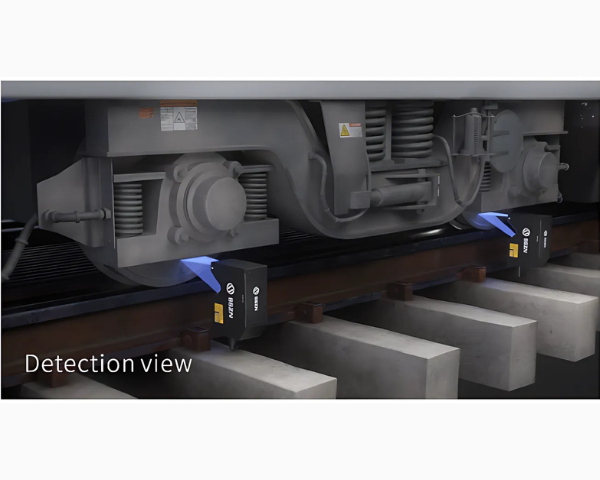

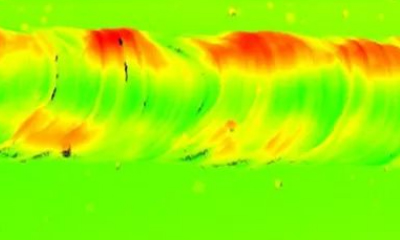

Physical Picture or Imaging Effect Picture

SinceVision Solution: SR5320 3D Laser Profiler

01Real-Time Analysis: Delivers instant data to detect issues like flat spots or uneven wear, ensuring timely maintenance decisions.

02Robust Design: Engineered for challenging railway environments, withstanding vibrations, dust, and temperature variations.

03Ultra-Fast Scanning: Captures detailed 3D profiles at speeds of up to 67K/s, enabling efficient inspection of moving trains or large volumes of wheel sets.

Camera Selection

| Model number | SR5320 | |||

| Reference distance (CD) | 500mm | |||

| Measuring range | Z-axis height (FS) | 510mm | ||

| X-axis width | Near side | 360mm | ||

| Reference distance | 470mm | |||

| Remote side | 640mm | |||

| Light source | Light source wavelength | 450nm blue light | ||

| Laser class | 3R | |||

| Laser output power | 50mW | |||

| Repetition accuracy | Z-axis (height) | 7.5μm | ||

| X-axis (width) | 50μm | |||

| linearity | Z-axis (height) | ±0.02% of F.S. | ||

| Contour data interval | X-axis (width) | 200μm | ||

| X-axis contour points | 3200 | |||

| Reflection Angle (°) | 35 | |||

| Scanning speed (Hz) | 2500 ~ 67000 | |||

| Dimension (mm) | 460×92.5×62 | |||

| Weight (g) | 1900 | |||

| Temperature characteristic | 0.02% F.S./℃ | |||

| Encoder input | Single-ended, differential encoder is supported | |||

| Input/output | One 100Base-TX/1000Base-T Ethernet interface | |||

| Operation Temperature | 0~50℃ | |||

| Storage Temperature | -20~70℃ | |||

| Working Humidity | 35% to 85% without condensation | |||

| ESD Protection | Contact discharge 4kV, air discharge 8kV, in accordance with IEC 61000-4-2 standards | |||

| EFT protection | Power port 2kV/5 or 100kHz, signal port 1kV/5 or 100kHz, in accordance with IEC 61000-4-4 standards | |||

| Impact | 50Gs/3ms per axis, in accordance with IEC 68-2-27 Ea standard | |||

| Vibration | 10Gs (10-500Hz), compliant with IEC 68-2-6 Fc standard | |||

| degrees of protection provided by enclosure | IP67, in accordance with IEC 60529 standard | |||