Auto Parts Measurement with SinceVision 3D Laser Profiler

Industry pain points and demands

Measurement Parameter: Flatness

Accuracy Standard: Repeatability of 0.07mm

In the highly demanding automotive industry, ensuring the precision of small metal parts is critical for safety, functionality, and assembly efficiency. SinceVision’s SR7080 3D Laser Profiler is designed to deliver high-accuracy measurements tailored to the rigorous requirements of automotive manufacturing.

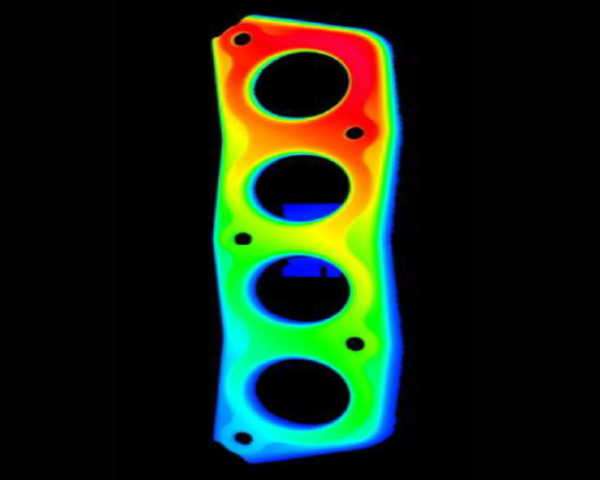

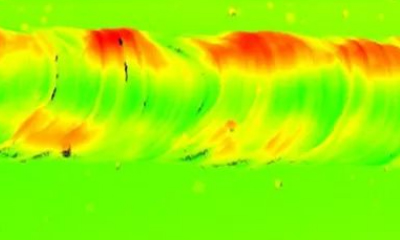

Physical Picture or Imaging Effect Picture

SinceVision Solution: SR7080 3D Laser Profiler

01High Precision: The SR7080 3D Laser Profiler ensures repeatable and reliable flatness measurement with sub-millimeter accuracy, meeting strict automotive quality standards.

02Rapid Inspection: Fast data acquisition speeds streamline production processes, reducing inspection time without compromising accuracy.

03Enhanced Reliability: Advanced 3D laser profiling technology minimizes errors and provides consistent results, ensuring flawless auto parts production.

Camera Selection

| Model number | SR7080 | |||

| Reference distance (CD) | 80mm | |||

| Measuring range | Z-axis height (FS) | 12mm | ||

| X-axis width | Near side | 57.5mm | ||

| Reference distance | 60mm | |||

| Remote side | 62.8mm | |||

| Light source | Light source wavelength | 405nm blue light | ||

| Laser class | 2M | |||

| Laser output power | 10mW | |||

| Repetition accuracy | Z-axis (height) | 0.4μm | ||

| X-axis (width) | 5μm | |||

| linearity | Z-axis (height) | ±0.05% F.S. | ||

| Contour data interval | X-axis (width) | 20μm | ||

| X-axis contour points | 3200 | |||

| Reflection Angle (°) | 37 | |||

| Scanning speed (Hz) | 2500 ~ 10000 | |||

| Dimension (mm) | 143.5×93×48 | |||

| Weight (g) | 730 | |||

| Temperature characteristic | 0.02% F.S./℃ | |||

| Encoder input | Single-ended, differential coders are supported | |||

| Input/output | 1 RS232 interface, 1 100Base-TX/1000Base-T Ethernet interface | |||

| Operation Temperature | 0~40℃ | |||

| Storage Temperature | -20~70℃ | |||

| Working Humidity | 35% to 85% without condensation | |||

| ESD Protection | Contact discharge 4kV, air discharge 8kV, in accordance with IEC 61000-4-2 standards | |||

| EFT protection | Power port 2kV/5 or 100kHz, signal port 1kV/5 or 100kHz, in accordance with IEC 61000-4-4 standards | |||

| Impact | 50Gs/3ms per axis, in accordance with IEC 68-2-27 Ea standard | |||

| Vibration | 10Gs(10-500Hz)符合 IEC 68-2-6 Fc标准标准 | |||

| degrees of protection provided by enclosure | IP67, in accordance with IEC 60529 standard | |||