Pre- and Post-Wrapping Inspection for Lithium Battery Appearance and Dimensions

In lithium battery production, appearance and dimensional accuracy must be strictly controlled both before and after the wrapping stage. Any surface defects or dimensional inconsistencies can affect not only the product’s visual appeal but also its structural integrity and downstream assembly.

One major challenge is post-wrapping appearance inspection. The blue protective film applied during wrapping is prone to issues such as scratches, bubbles, and wrinkles. Its optical properties make defect features harder to detect, leading to high false rejection or missed defect rates.

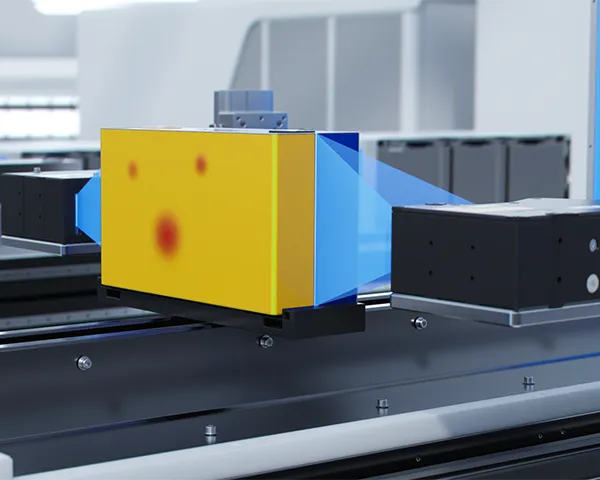

With SinceVision’s advanced 3D vision inspection system, manufacturers can perform rapid, accurate inspections for both defect detection and dimensional validation, helping to maintain high product standards and reduce rework.

Before Wrapping:

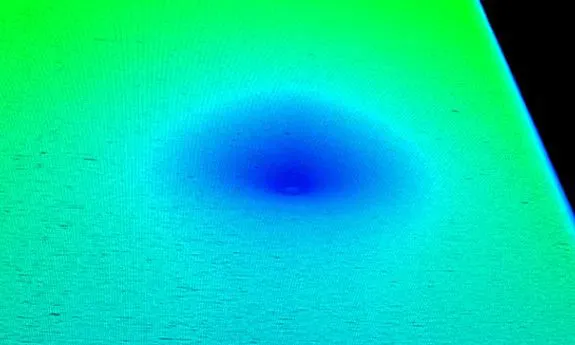

The 3D system scans the battery case surface, edges, and corners to identify surface flaws like dents, bumps, and scratches. Using multi-angle image stitching, the system also performs flatness measurements of the casing, ensuring only defect-free parts move into the wrapping process.

After Wrapping:

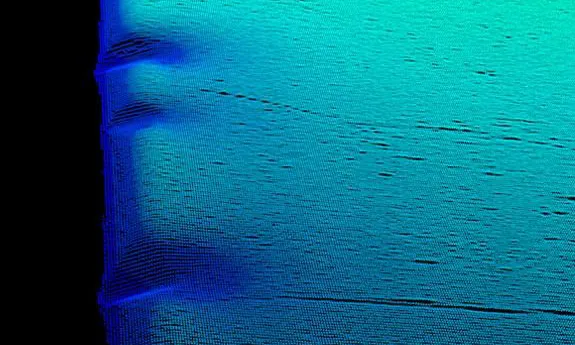

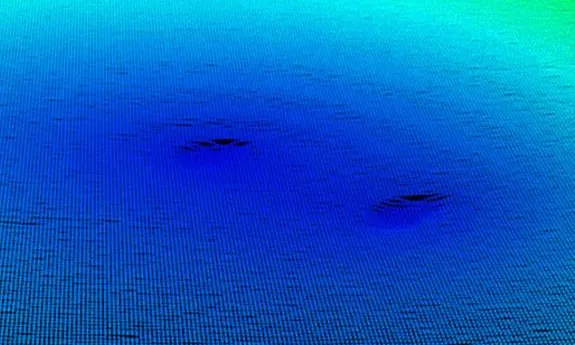

The system performs five-surface inspection (excluding the top cover) to identify defects in the blue film layer. It also measures length, width, and height. For the top cover, the system detects pole defects, measures height deviations, and checks for parallelism — preventing any dimensional or appearance anomalies from entering the module (Pack) stage.

Effect Display

SinceVision Solution: SR7140 3D Laser Profiler

Camera Selection

| Model number | SR7140 | |||

| Reference distance (CD) | 140mm | |||

| Measuring range | Z-axis height (FS) | 24mm | ||

| X-axis width | Near side | 89mm | ||

| Reference distance | 95mm | |||

| Remote side | 96mm | |||

| Light source | Light source wavelength | 405nm blue light | ||

| Laser class | 2M | |||

| Laser output power | 10mW | |||

| Repetition accuracy | Z-axis (height) | 0.5μm | ||

| X-axis (width) | 8μm | |||

| linearity | Z-axis (height) | ±0.05% F.S. | ||

| Contour data interval | X-axis (width) | 30μm | ||

| X-axis contour points | 3200 | |||

| Reflection Angle (°) | 28 | |||

| Scanning speed (Hz) | 2500 ~ 10000 | |||

| Dimension (mm) | 143×93.2×48.3 | |||

| Weight (g) | 730 | |||

| Temperature characteristic | 0.02% F.S./℃ | |||

| Encoder input | Single-ended, differential coders are supported | |||

| Input/output | 1 RS232 interface, 1 100Base-TX/1000Base-T Ethernet interface | |||

| Operation Temperature | 0~50℃ | |||

| Storage Temperature | -20~70℃ | |||

| Working Humidity | 35% to 85% without condensation | |||

| ESD Protection | Contact discharge 4kV, air discharge 8kV, in accordance with IEC 61000-4-2 standards | |||

| EFT protection | Power port 2kV/5 or 100kHz, signal port 1kV/5 or 100kHz, in accordance with IEC 61000-4-4 standards | |||

| Impact | 50Gs/3ms per axis, in accordance with IEC 68-2-27 Ea standard | |||

| Vibration | 10Gs(10-500Hz)符合 IEC 68-2-6 Fc标准标准 | |||

| degrees of protection provided by enclosure | IP67, in accordance with IEC 60529 standard | |||