Lithium Battery Module Side Seam Welding Inspection with 3D Laser Profiler

Industry pain points and demands

In lithium battery manufacturing, the structural strength and sealing performance of battery modules are directly influenced by the quality of side seam welding. Poor welds can compromise the module’s durability, safety, and energy efficiency.

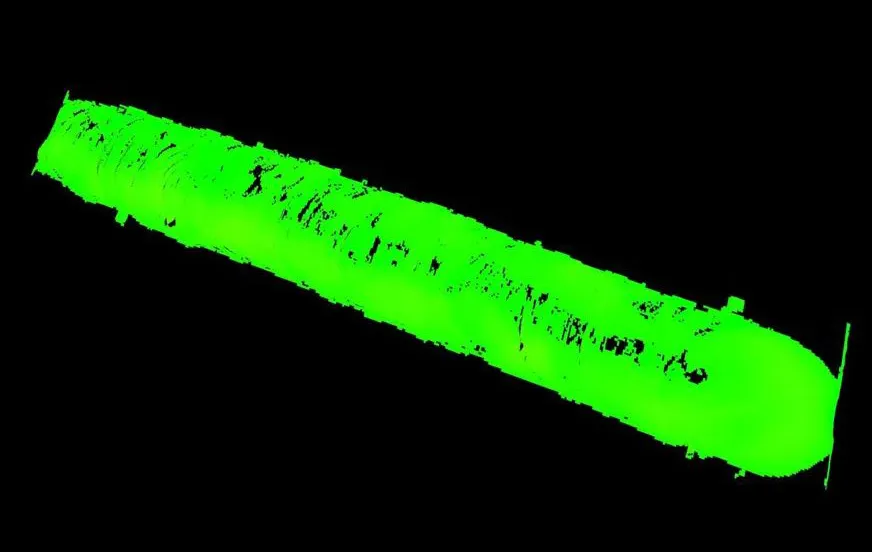

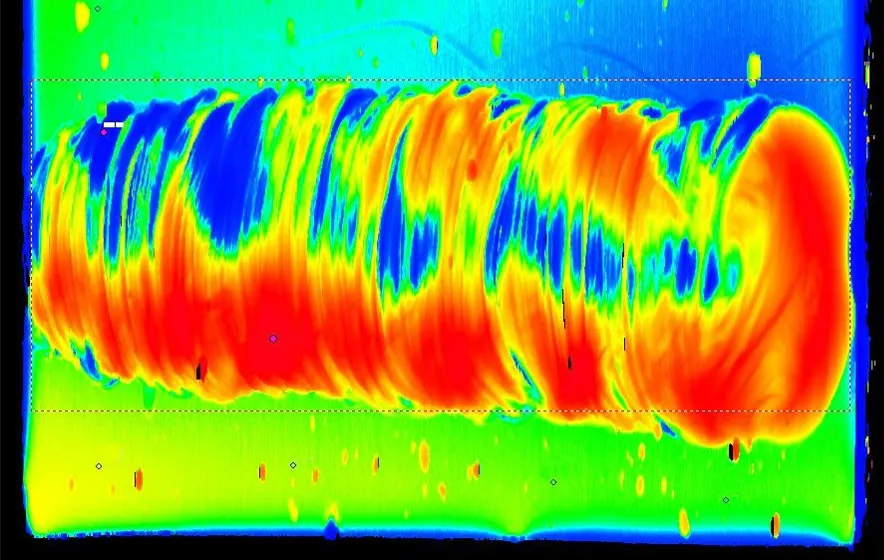

SinceVision’s advanced 3D laser profiler addresses this challenge by performing real-time, full-surface scanning of the module’s side seam. The system compares the captured point cloud data against a reference model to accurately detect weld defects, including pores, cracks, and incomplete penetration, ensuring each weld meets strict quality and safety standards.

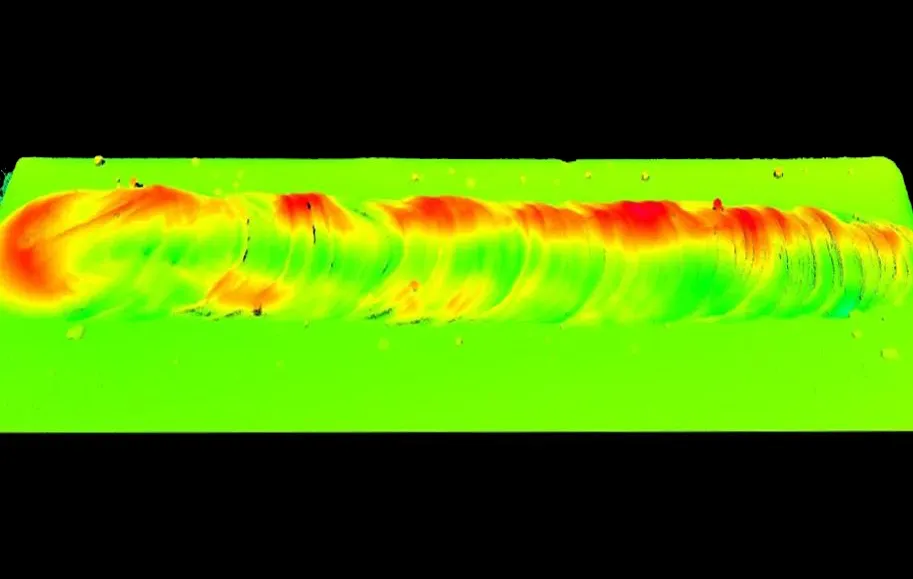

Effect Display

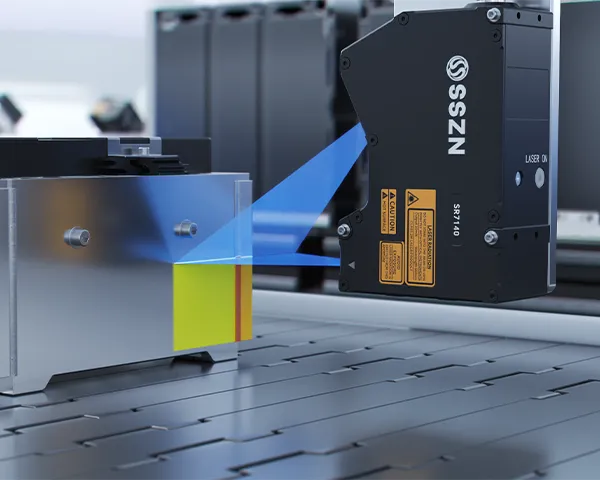

SinceVision Solution: SR7140 3D Laser Profiler

01 Fast and Accurate Defect Detection: SinceVision’s measurement system enables high-speed scanning at up to 100 mm/s, making it ideal for in-line quality control on high-throughput production lines. It can stably identify weld defects larger than 0.5mm × 0.5mm, ensuring reliable, high-resolution inspection.

02High Cost-Performance Value: Compared with laser profiler of similar configuration, SinceVision offers a clear cost advantage while maintaining high accuracy and durability. Its efficient integration and robust performance provide long-term value for lithium battery manufacturers focused on quality and cost control.

Camera Selection

| Model number | SR7140 | |||

| Reference distance (CD) | 140mm | |||

| Measuring range | Z-axis height (FS) | 24mm | ||

| X-axis width | Near side | 89mm | ||

| Reference distance | 95mm | |||

| Remote side | 96mm | |||

| Light source | Light source wavelength | 405nm blue light | ||

| Laser class | 2M | |||

| Laser output power | 10mW | |||

| Repetition accuracy | Z-axis (height) | 0.5μm | ||

| X-axis (width) | 8μm | |||

| linearity | Z-axis (height) | ±0.05% F.S. | ||

| Contour data interval | X-axis (width) | 30μm | ||

| X-axis contour points | 3200 | |||

| Reflection Angle (°) | 28 | |||

| Scanning speed (Hz) | 2500 ~ 10000 | |||

| Dimension (mm) | 143×93.2×48.3 | |||

| Weight (g) | 730 | |||

| Temperature characteristic | 0.02% F.S./℃ | |||

| Encoder input | Single-ended, differential coders are supported | |||

| Input/output | 1 RS232 interface, 1 100Base-TX/1000Base-T Ethernet interface | |||

| Operation Temperature | 0~50℃ | |||

| Storage Temperature | -20~70℃ | |||

| Working Humidity | 35% to 85% without condensation | |||

| ESD Protection | Contact discharge 4kV, air discharge 8kV, in accordance with IEC 61000-4-2 standards | |||

| EFT protection | Power port 2kV/5 or 100kHz, signal port 1kV/5 or 100kHz, in accordance with IEC 61000-4-4 standards | |||

| Impact | 50Gs/3ms per axis, in accordance with IEC 68-2-27 Ea standard | |||

| Vibration | 10Gs(10-500Hz)符合 IEC 68-2-6 Fc标准标准 | |||

| degrees of protection provided by enclosure | IP67, in accordance with IEC 60529 standard | |||