Laser Profiler for BGA Package Solder Ball Flatness

Industry pain points and demands

In BGA package manufacturing, precise solder ball flatness measurement is crucial. It directly impacts the mechanical and electrical performance of solder joints. Accurate measurement is also a core quality control method for meeting the demands of package miniaturization and high reliability. Rigorous flatness testing ensures every chip meets high standards, providing a competitive market advantage.

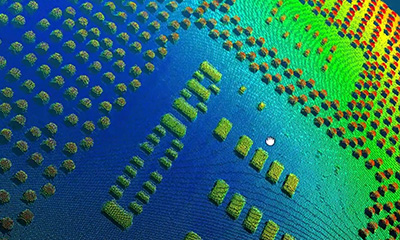

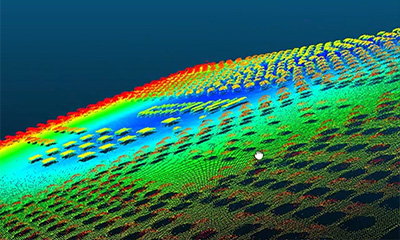

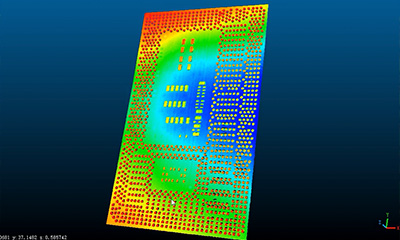

Imaging Effect

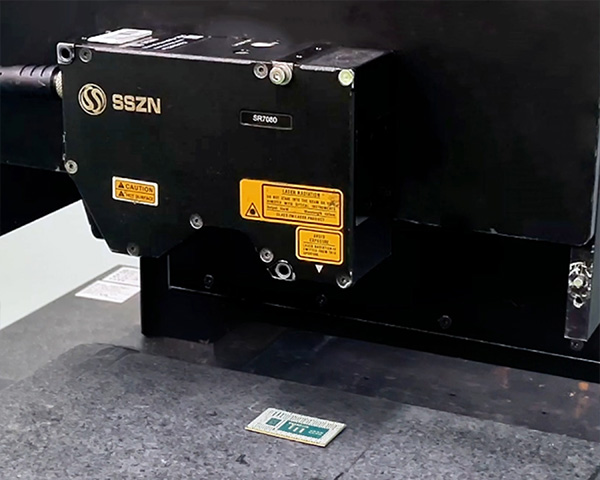

SinceVision Solution: SR7080 3D Laser Profiler

01High-Speed 3D Mapping: The SinceVision SR7080 3D laser profiler sensor uses a 10,000 Hz high sampling frequency to quickly generate a complete 3D point cloud map of chip solder joints.

02Precise Parameter Detection: With 0.4μm repeat accuracy, it precisely detects key parameters such as solder ball flatness, height, and apex flatness.

03Reliable and Consistent Results: Ensures the reliability and consistency of test results with 3200 x-axis contour points

Camera Selection

| Model number | SR7080 | |||

| Reference distance (CD) | 80mm | |||

| Measuring range | Z-axis height (FS) | 12mm | ||

| X-axis width | Near side | 57.5mm | ||

| Reference distance | 60mm | |||

| Remote side | 62.8mm | |||

| Light source | Light source wavelength | 405nm blue light | ||

| Laser class | 2M | |||

| Laser output power | 10mW | |||

| Repetition accuracy | Z-axis (height) | 0.4μm | ||

| X-axis (width) | 5μm | |||

| linearity | Z-axis (height) | ±0.05% F.S. | ||

| Contour data interval | X-axis (width) | 20μm | ||

| X-axis contour points | 3200 | |||

| Reflection Angle (°) | 37 | |||

| Scanning speed (Hz) | 2500 ~ 10000 | |||

| Dimension (mm) | 143.5×93×48 | |||

| Weight (g) | 730 | |||

| Temperature characteristic | 0.02% F.S./℃ | |||

| Encoder input | Single-ended, differential coders are supported | |||

| Input/output | 1 RS232 interface, 1 100Base-TX/1000Base-T Ethernet interface | |||

| Operation Temperature | 0~40℃ | |||

| Storage Temperature | -20~70℃ | |||

| Working Humidity | 35% to 85% without condensation | |||

| ESD Protection | Contact discharge 4kV, air discharge 8kV, in accordance with IEC 61000-4-2 standards | |||

| EFT protection | Power port 2kV/5 or 100kHz, signal port 1kV/5 or 100kHz, in accordance with IEC 61000-4-4 standards | |||

| Impact | 50Gs/3ms per axis, in accordance with IEC 68-2-27 Ea standard | |||

| Vibration | 10Gs(10-500Hz)符合 IEC 68-2-6 Fc标准标准 | |||

| degrees of protection provided by enclosure | IP67, in accordance with IEC 60529 standard | |||