Stacking Machine Inspection: Separator Deviation, Electrode Damage, and Positioning Detection

Industry pain points and demands

In the advanced lithium battery production industry, particularly for stacked batteries, manufacturers face several critical challenges:

Separator Deviation: Misalignment of separators can lead to reduced battery efficiency and potential safety issues.

Electrode Damage Detection: Undetected damage to electrode edges can compromise battery performance and longevity.

Precise Electrode Positioning: Inaccurate positioning of electrodes can result in suboptimal battery construction and reduced capacity.

These challenges, if not addressed, can significantly impact production efficiency, yield, and overall product quality in the highly competitive lithium battery market.

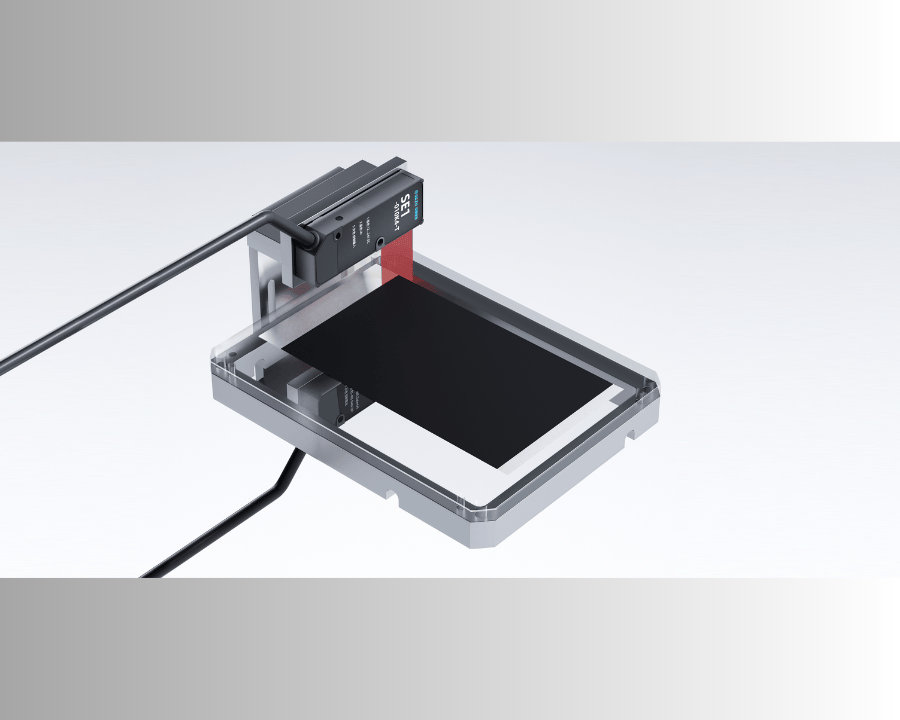

SinceVision Solutions: SE2 Series Through-Beam Edge Sensor

01High-Speed, High-Precision Detection: With a sampling frequency of 4kHz and a response time of just 250 µs, the SE2 Series ensures rapid and accurate detection of separator deviations, electrode damage, and positioning across various workstations in the stacking machine.

02Versatile Material Compatibility: The SE2 Series demonstrates excellent correction capabilities for separators with varying light transmittance properties, ensuring consistent performance across different material types used in battery production.

03Superior Electrode Damage Detection: The sensor's advanced technology provides a significant advantage in identifying even minor electrode edge damage, helping to maintain high product quality and reduce waste.

Camera Selection

| Technical specifications of SinceVision sensors | |

| Measuring range | Edge: ±12mm |

| Transmitter-receiver distance | Max. 200mm |

| Light source | Semiconductor red laser |

| linearity | When the distance between transceiver and receiver is 100mm: ±0.4%F.S. (±96μm) |

| Repetition accuracy | 50μm |

| Response time | 0.5ms |

| interface | RS485 |

| Ambient temperature/humidity | -10℃ ~ +50℃/35 ~ 85%RH (no condensation freezing) |

| Store temperature/humidity | -20℃ ~ +60℃/35 ~ 85%RH (no condensation freezing) |

| Protection class | IP67 |

| Shell material | Aluminium alloy |

| dimension | 80mm x 33mm x 15 mm |

| Controller main index | ||

| Model number | SEA-DM2-A/V | SEA-DM2 |

| Number of sensor head connections | Max. 2 pairs of sensor heads | Max. 2 pairs of sensor heads |

| Sensor head connection mode | M8 6-pin connector | M8 6-pin connector |

| Sensor head communication mode | RS-485 (maximum 20m cable) | RS-485 (maximum 20m cable) |

| Display measurement | TFT screen | TFT screen |

| Display light | Power indicator: Green; Output indicator: Red | Power indicator: Green; Output indicator: Red |

| I/O external input | 1 way (also valid for sensor head channel 1/ Channel 2) | |

| I/O switching output | 2 output PNP/NPN Optional open collector Max. 100mA/DC 24V Residual voltage less than 1.8V | |

| I/O analog output | 2 output analog current/voltage Optional, current: 4 ~ 20mA (maximum load 300Ω) or voltage: 0 ~ 10V (output resistance 100Ω) | |

| Protection Level | IP50 | IP50 |

| Operating environment Temperature/Humidity | -20 ° C to +50 ° C /35 to 85%RH (without condensation freezing) | -20 ° C to +50 ° C /35 to 85%RH (without condensation freezing) |

| Storage environment temperature/humidity | -20 ℃~+70 ℃/35~85% RH (without condensation or freezing) | -20 ℃~+70 ℃/35~85% RH (without condensation or freezing) |

| Installation | DIN rail installation setting | DIN rail installation setting |

| shell material | PC+ glass fiber | PC+ glass fiber |

| EtherCAT communication unit technical specifications | |

| EtherCAT distance between nodes | Max. 100m |

| EtherCAT Transfer speed | 100Mbps |

| EtherCAT mapping function | Process data communication, mailbox communication |

| Connect sensor connected models | Controller SEA-DM2 |

| Connection Number of connections that can be made to sensors | Maximum 8 controllers (16 pairs of sensing heads) |

| Connection sensor connectable form | 10-pin connector |

| PDO communication data transmission | support |

| SDO communication data transfer | support |

| Use ambient temperature/humidity | -20℃ ~ +50℃/35 ~ 85%RH (no condensation freezing) |

| Storage environment temperature/humidity | -40℃ ~ +70℃/35 ~ 85%RH (no condensation freezing) |

| Protection class | IP50 |

| install | 35mm DIN Rail (conductive) |

| Shell material | PC+ Glass fiber |

| Model description of the deviation correcting sensor | |

| Transmitting sensing head | SE1-010K4-T |

| Receiving sensor head | SE1-010K4-R |

| controller | SEA-DM2-A/V; SEA-DM2 |

| EtherCAT Universal Communication module | SU1-EC |

| 2m long Y-shaped cable | SCB-EY-HA3-2m |

| 5m long Y-shaped cable | SCB-EY-HA3-5m |

| 5m long extension cable | SCB-EF-HA3-5m |