Smartphone Middle Frame FPC Object Detection with 3D Laser Profilers

Industry pain points and demands

In the fast-paced consumer electronics industry, particularly in mobile phone manufacturing, the increasing complexity and integration of components present significant challenges. Flexible Printed Circuits (FPCs) are integral to modern smartphones, but their delicate nature makes them susceptible to surface contamination and foreign object defects during the manufacturing process. These defects can lead to product malfunction and decreased reliability. To ensure high product quality and minimize defects, efficient and accurate detection of foreign objects on FPCs is crucial.

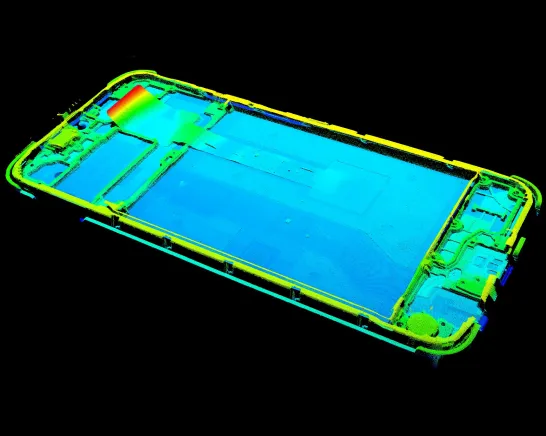

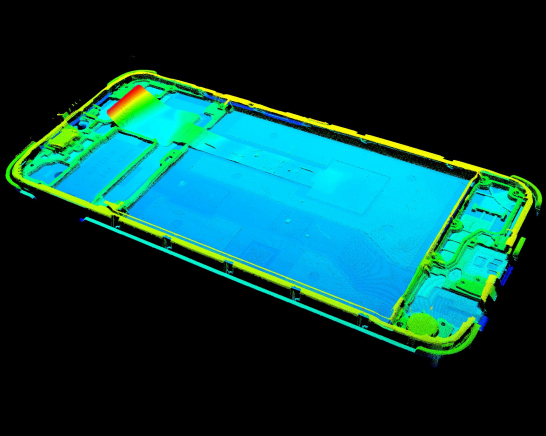

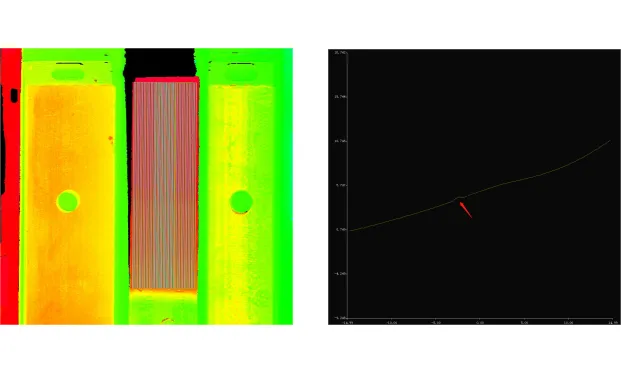

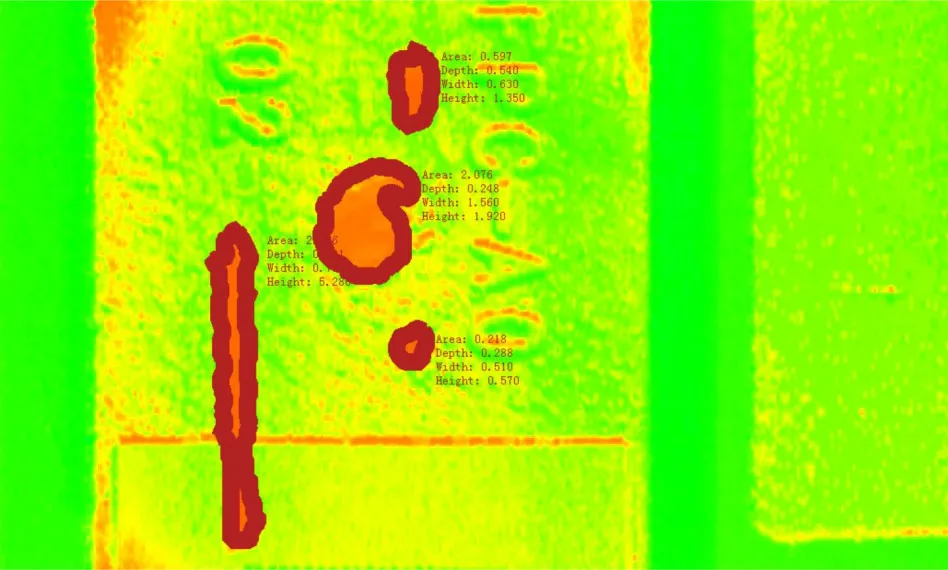

Physical Picture or Imaging Effect Picture

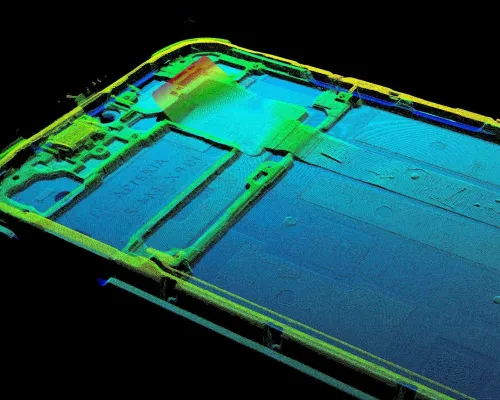

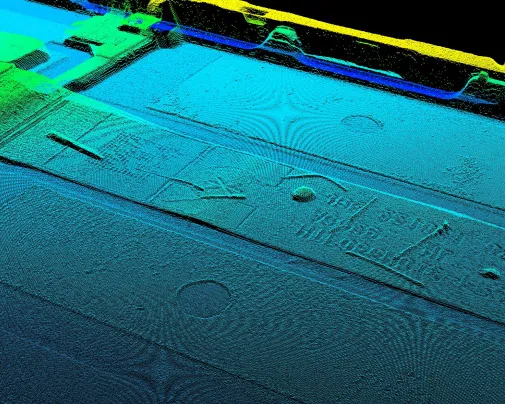

Defect Detection Location

SinceVision Solutions: SR7140 3D Laser Profiler

01High-Resolution Detection: The SinceVision SR7140 3D Laser Profiler is engineered to detect minute foreign objects on FPCs with exceptional precision. It can identify objects as small as 0.5mm x 0.5mm x 0.3mm, ensuring that even the smallest contaminants are detected and addressed.

02Rapid and Efficient Scanning: The SR7140 offers rapid evaluation, with a scanning time of just 6.5 seconds. This high-speed detection capability enables manufacturers to maintain high throughput without compromising on quality, optimizing both efficiency and product quality.

03Cost-Effective and Stable Performance: The SR7140 provides a cost-effective solution with stable performance, making it an ideal choice for manufacturers seeking to enhance their quality control processes without significant capital investment. Additionally, SinceVision offers a rich product matrix, catering to diverse application scenarios and requirements.

Camera Selection

| Model number | SR7140 | |||

| Reference distance (CD) | 140mm | |||

| Measuring range | Z-axis height (FS) | 24mm | ||

| X-axis width | Near side | 89mm | ||

| Reference distance | 95mm | |||

| Remote side | 96mm | |||

| Light source | Light source wavelength | 405nm blue light | ||

| Laser class | 2M | |||

| Laser output power | 10mW | |||

| Repetition accuracy | Z-axis (height) | 0.5μm | ||

| X-axis (width) | 8μm | |||

| linearity | Z-axis (height) | ±0.05% F.S. | ||

| Contour data interval | X-axis (width) | 30μm | ||

| X-axis contour points | 3200 | |||

| Reflection Angle (°) | 28 | |||

| Scanning speed (Hz) | 2500 ~ 10000 | |||

| Dimension (mm) | 143×93.2×48.3 | |||

| Weight (g) | 730 | |||

| Temperature characteristic | 0.02% F.S./℃ | |||

| Encoder input | Single-ended, differential coders are supported | |||

| Input/output | 1 RS232 interface, 1 100Base-TX/1000Base-T Ethernet interface | |||

| Operation Temperature | 0~50℃ | |||

| Storage Temperature | -20~70℃ | |||

| Working Humidity | 35% to 85% without condensation | |||

| ESD Protection | Contact discharge 4kV, air discharge 8kV, in accordance with IEC 61000-4-2 standards | |||

| EFT protection | Power port 2kV/5 or 100kHz, signal port 1kV/5 or 100kHz, in accordance with IEC 61000-4-4 standards | |||

| Impact | 50Gs/3ms per axis, in accordance with IEC 68-2-27 Ea standard | |||

| Vibration | 10Gs(10-500Hz)符合 IEC 68-2-6 Fc标准标准 | |||

| degrees of protection provided by enclosure | IP67, in accordance with IEC 60529 standard | |||