Talking Pen Thickness Detection with 3D Laser Profilers

Industry pain points and demands

In the consumer electronics industry, particularly in the production of talking pens, maintaining precise dimensions is critical. The thickness of a talking pen affects not only the assembly of its components but also influences screen display quality and grip balance. Any variations in thickness can lead to functional issues, impacting user experience and product reliability. Therefore, it is essential to implement effective thickness control measures during the manufacturing process.

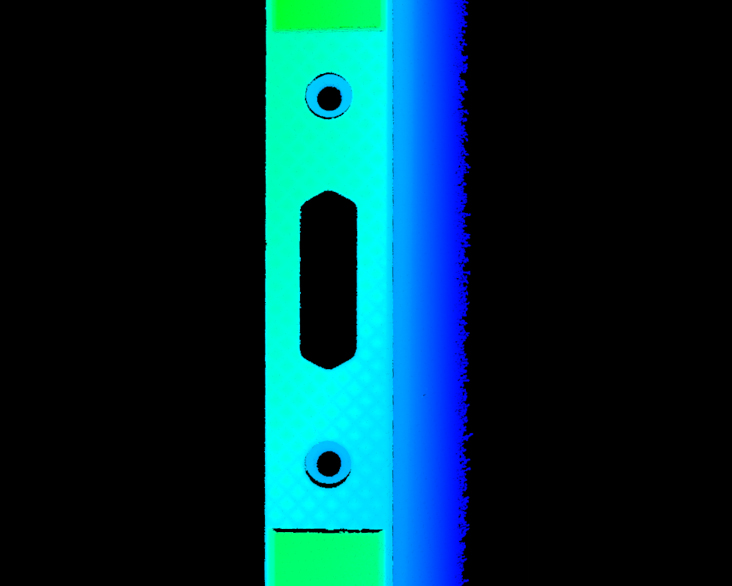

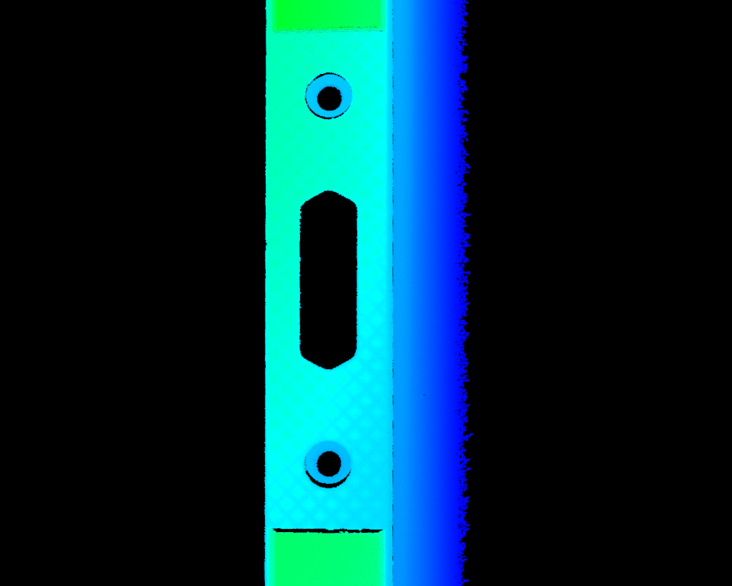

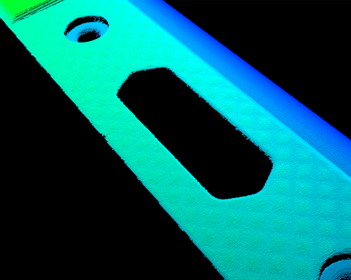

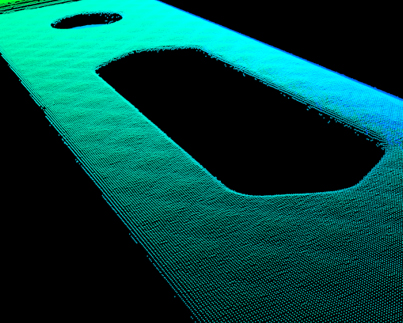

Physical Picture or Imaging Effect Picture

SinceVision Solutions: SR8060 3D Laser Profiler

01High Precision Measurement: The SR8060 3D Laser Profiler delivers exceptional dynamic repeatability accuracy with a maximum thickness measurement precision of 0.01mm. This ensures that manufacturers can detect even the slightest variations in thickness, maintaining stringent quality standards.

02Cost-Effective Performance: The SR8060 offers high cost performance without compromising on stability. This makes it an ideal solution for manufacturers looking to enhance their quality control processes while keeping operational costs manageable.

03Customized Solutions for Small Fields of Vision: In the detection industry where high precision is required in small fields of vision, the SR8060 can be customized to meet specific application needs. This adaptability allows manufacturers to optimize their inspection processes for various talking pen designs.

Camera Selection

| Model number | SR8060 | |||

| Reference distance (CD) | 60mm | |||

| Measuring range | Z-axis height (FS) | 18mm | ||

| X-axis width | Near side | 26mm | ||

| Reference distance | 31mm | |||

| Remote side | 36mm | |||

| Light source | Light source wavelength | 405nm blue light | ||

| Laser class | 2M | |||

| Laser output power | 10mW | |||

| Repetition accuracy | Z-axis (height) | 0.2μm | ||

| X-axis (width) | 5μm | |||

| linearity | Z-axis (height) | ±0.02% of F.S. | ||

| Contour data interval | X-axis (width) | 12μm | ||

| X-axis contour points | 3200 | |||

| Reflection Angle (°) | 33 | |||

| Scanning speed (Hz) | 3200 ~ 67000 | |||

| Dimension (mm) | 124.5×84×55. 2 | |||

| Weight (g) | 630 | |||

| Temperature characteristic | 0.02% F.S./℃ | |||

| Encoder input | Single-ended, differential encoder is supported | |||

| Input/output | One 100Base-TX/1000Base-T Ethernet interface | |||

| Operation Temperature | 0~50℃ | |||

| Storage Temperature | -20~70℃ | |||

| Working humidity | 35% to 85% without condensation | |||

| ESD Protection | Contact discharge 4kV, air discharge 8kV, in accordance with IEC 61000-4-2 standards | |||

| EFT protection | Power port 2kV/5 or 100kHz, signal port 1kV/5 or 100kHz, in accordance with IEC 61000-4-4 standards | |||

| Impact | 50Gs/3ms per axis, in accordance with IEC 68-2-27 Ea standard | |||

| Vibration | 10Gs (10-500Hz), compliant with IEC 68-2-6 Fc standard | |||

| degrees of protection provided by enclosure | IP67, in accordance with IEC 60529 standard | |||