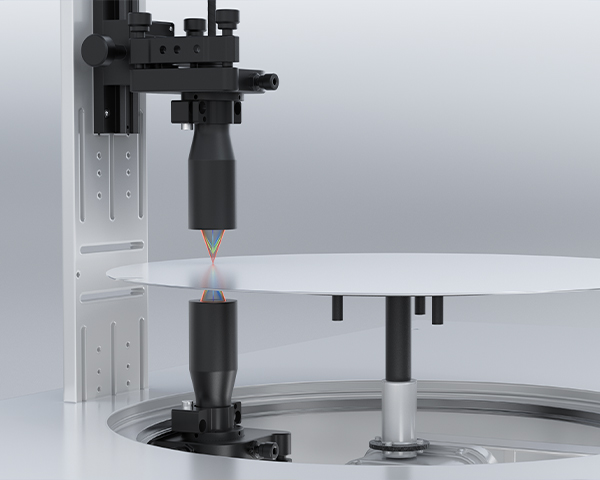

Through-Beam Measurement of Semiconductor Wafer Thickness with Spectral Confocal Displacement Sensor

As the foundational substrate for semiconductor chips, the thickness of a wafer plays a pivotal role in determining the chip's performance, reliability, and final yield rate. Accurate wafer thickness measurement ensures manufacturing stability and consistency, which ultimately enhances the overall product quality.

Semiconductor wafer thickness directly influences chip performance and manufacturing consistency, posing several challenges:

Material Variability: Wafers with diverse thin-film layers, including highly transparent and reflective materials, create unstable signal feedback.

Precision Requirements: Micron-level accuracy is critical for ensuring product quality and yield rates.

Speed: Accurate measurements must be maintained on high-speed production lines.

SinceVision Solution: SCI04025 Spectral Confocal Displacement Sensor

Camera Selection

| Fixture model | SCI04025 | |

| controller | SCI501A/SCI502A/SCI501B/SCI502B | |

| Fixture Model | SCI-01 | |

| Spot size | 12μm | 25.2μm |

| Measuring range | 4mm | |

| Working distance | 16mm | |

| Axial resolution | 0.006μm | |

| straightness | ±0.8μm | |

| Angle characteristic | ±25° | |

| Minimum measurable thickness of transparent object | 130μm | |

| diameter | 30mm | |

| length | 114mm | |

| weight | 95g | |